Structural Engineering (New construction and structural upgrades for columns, racking and cranes)

Structural services available:

- Forklift damaged columns

- Undersized mezzanine columns

- Undersized racking

- Damaged racking

- Undersized roof joists

- Machine support structures

- Undersized crane structures

- Jib crane extensions

- Crane Modernization

- Hoist, trolley & crane upgrades

- Control upgrades

OHSA Regulation 851, Section 72

72. (1) Where a structure is damaged to the extent that a collapse of the structure or any part of the structure is likely to occur and cause injury to a worker,

(a) the structure shall be braced and shored to prevent the collapse of the structure; or

(b) effective safeguards shall be provided to prevent access to the area. R.R.O. 1990, Reg. 851, s. 72 (1).

(2) The bracing and shoring or other safeguards prescribed by subsection (1) shall be installed progressively to ensure that a worker installing the bracing and shoring or other safeguards is not in danger. R.R.O. 1990, Reg. 851, s. 72 (2).

Structural Upgrade Engineering

Our structural engineering team combines an in-depth understanding of engineering principles, technological opportunities, construction processes, in-service use and regulatory frameworks – all of which are brought together in order to collaborate with our clients on a solution that satisfies each of these criteria.

Our structural engineers produce designs for new builds and retrofits that not only ensure successful solutions, but optimise the construction process and minimize maintenance costs along the way.

Your Perfect Solution Awaits!

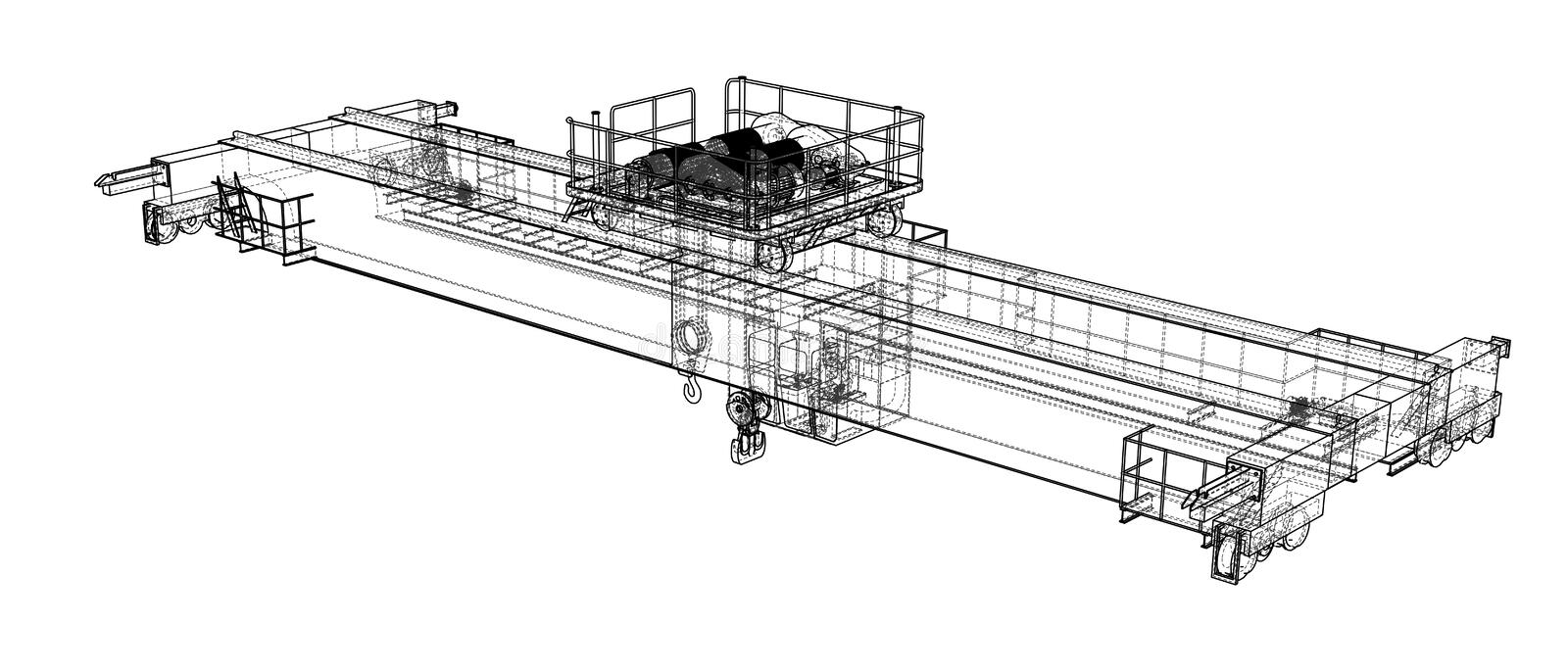

Next Hydrogen Large Industrial Gantry Crane

Our team performed the design, fabrication, welding and painting operations for their new, large custom gantry crane at our facility. The installation helped to improve our clients’ facility operations.

Outdoor maintenance travelers

A recent large-scale project has our team installing replacement “Maintenance Travellers” for the underside of a suspension bridge over the St. Lawrence river between Ontario and New York.

Custom Transfer Cart

One of our customers recently purchased a brand new laser cutting machine that increased production while reducing the footprint in their facility. But there was a problem.

- CWB Certified Welders (Steel and Aluminum)

- CWB certified for welding of Steel (CSA Standard W47.1, Division 2)

- CWB certified for welding of Aluminum (CSA Standard W47.2, Division 2)

- Professional Engineers Ontario

- CLAC

Structural Services

Upgrades

- Forklift damaged columns

- Undersized mezzanine columns

- Undersized racking

- Damaged racking

- Undersized roof joists

- Machine support structures

Crane Specific Upgrades

- Undersized crane structures

- Jib crane extensions

- Crane Modernization

- Hoist, trolley & crane upgrades

- Control upgrades

CAPABILITIES - WHAT SETS US APART

- Safety and quality; we are a safety company first and foremost. Our products and solutions are designed with a focus on exceptional quality while protecting your company and its employees.

- Creativity and innovation; we build exceptional and reliable products through innovation and a true customer first philosophy. We specialize in unique, custom and standard fabricated products.

- Our office and shop teams; In-house design, engineering teams, fabrication, installation and inspection teams.

- Our locations; with multiple locations across Ontario, we are well positioned to support all regions within the province as well as other Canadian provinces. 30,000 sq/ ft. of fabrication space including machine shop, fabrication shop, paint booth, and assembly area.

- Experience and longevity; Liftsafe has been recognized as an industry leader for more than 25 years in the fabrication space, working alongside some of the largest manufacturing, industrial, warehousing, energy, aviation, automotive, construction and defense companies in North America.

Related Products

Equipment Repairs

At Liftsafe Engineering & Service Group, equipment repairs and service are where we shine. Our vision and goal is simple: to get you up and running as quickly, safely, and cost-efficiently as possible.

Engineering Design

From the cranes that can add capacity to your facility to the ergonomic material handling device that can eliminate work-related repetitive strain injuries: Liftsafe brings together our design engineering team and cutting-edge design software to deliver turnkey solutions for our clients in multiple industries.

Inspections

Helping business owners and plant managers protect their business and employees from a safety and regulatory standpoint by providing turnkey inspection services that ensure your equipment is certified “safe” and documented.

About Liftsafe Engineering & Service Group

Resource Center

Customer Service

Request a quote

We offer a huge selection of products and quick quotes for what you’re looking for.

Have questions?

Give us a call. Our friendly customer service staff are on hand and ready to help you.