End Effectors

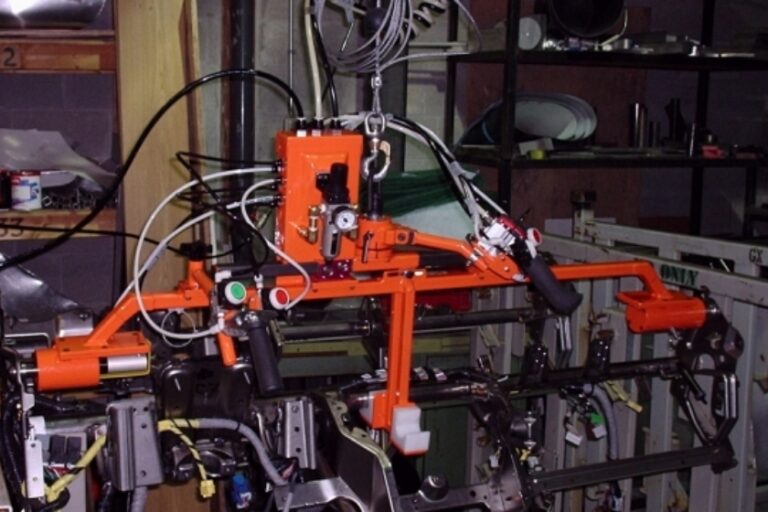

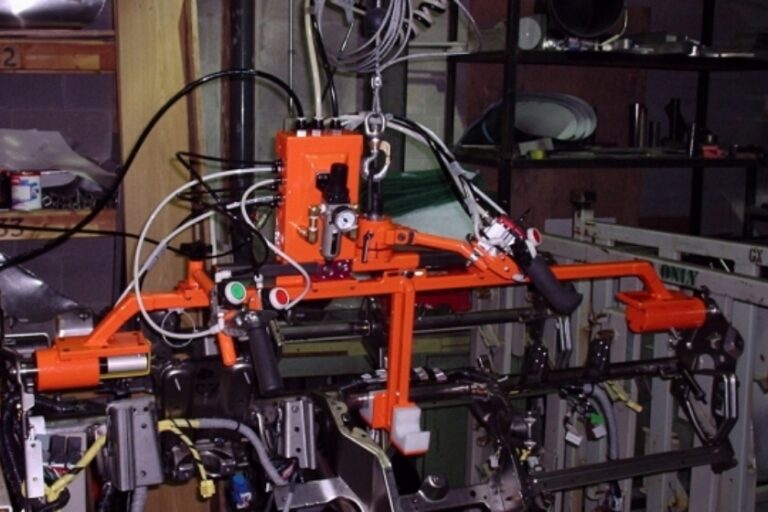

End Effectors are devices that are able to complete a wide variety of tasks that can be designed to mimic everything from fine motor skills to simple lifts of awkward shapes. They are attached to the end of an overhead lifting system (crane and hoist) allowing operators to complete tasks that would normally cause repetitive strain, unsafe lifting and fatigue.

With over 25 years of experience building custom End Effectors for multiple sectors (Manufacturing and Automotive, Food and Beverage, Pharmaceutical and Hospital, Warehouse and Retail to name a few), we can design, engineer, build, install, and service custom systems designed with your specific application in mind backed by our in-house team of Professional Engineers.

With our complete design, engineering, fabrication, and installation teams, we are able to rigorously test and refine our systems in order to create solutions for whatever material handling problem you are looking to solve.

Talk to a specialist today

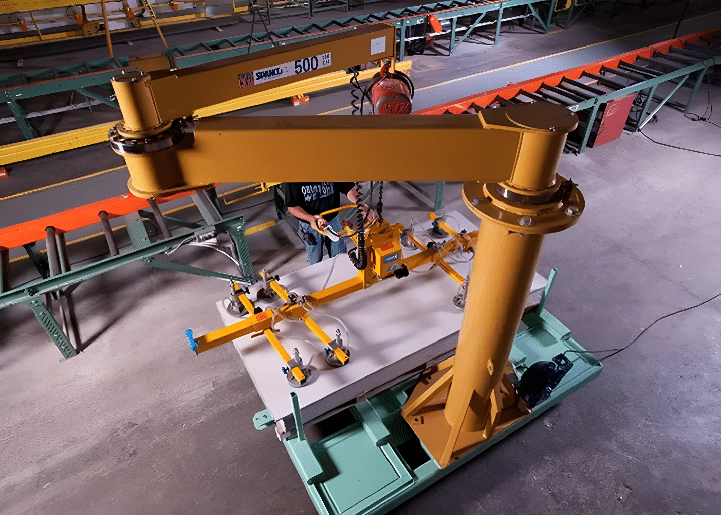

Vacuum End Effectors

Vacuum End Effectors do much more than just lift objects up, they can also rotate and tilt products and are able to lift a number of different irregular or flat surfaces and materials. Projects completed by Liftsafe in the past include wood, steel, cardboard, aluminum, glass and ceramic. Objects include various car parts, electrical panels, sinks, patio doors and packaging among many others.

Designed to specific loading capacity.

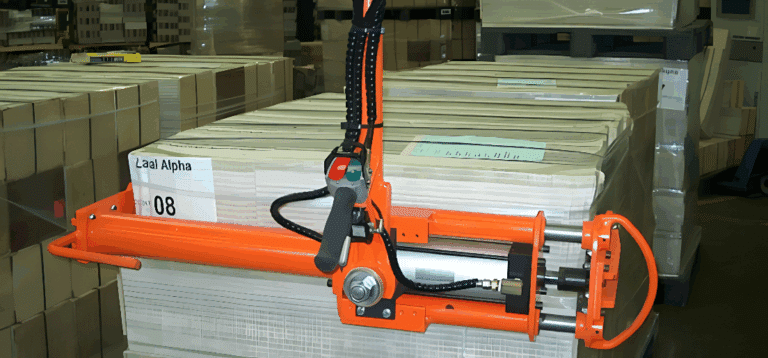

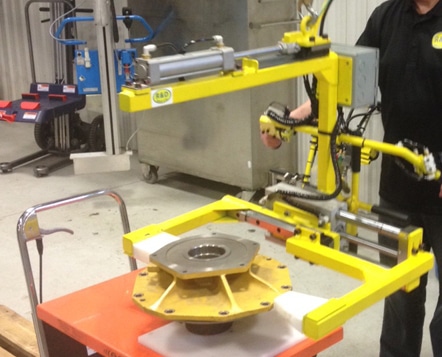

Gripper End Effectors

A variety of styles are available for Gripper End Effector Systems, such as the well-known two-finger grippers found in many industrial overhead lifting systems.

Due to the amount of solutions these systems can provide, there are very few standard products. To guarantee optimum performance, gripper designs are frequently customized. The manufacturing, automotive, food and beverage, pharmaceutical, hospital, warehouse, and retail industries all use these adaptable grippers for their various material handling needs.

Designed to specific loading capacity.

Magnetic End Effectors

Magnetic End of Arm Tooling devices are the standard offering for industries handling large steel components, such as sheet metal, automotive parts, construction components, machine dies, and hydraulic cylinders.

With their magnetic qualities enabling safe and dependable lifting operations, these systems, which are built for efficiency, perform exceptionally well in industries such as automotive manufacturing where metal parts are widely used.

Designed to specific loading capacity.

Key features

Safety First

Products engineered with uncompromising safety and quality to protect your people.

Innovation Driven

Custom and standard solutions built with creativity, reliability, and a customer-first focus.

In-House Expertise

Design, engineering, fabrication, installation, and inspection all under one roof.

Strategic Locations

30,000 sq. ft. of fabrication space across Ontario, serving clients nationwide.

Proven Experience

25+ years as a trusted partner to leading industries across North America.

Your Perfect Solution Awaits!

We can do it all

Liftsafe offers lifting systems and services for every aspect of your facility. Our specialists have the industry expertise to recommend the best system for upgrading and optimizing your space. Rely on our industry experts to do a walkthrough of your facility to find the right standard or custom lifting solution. From there our in-house engineering team will design your system to meet all regulatory standards which then gets manufactured by CWB qualified welders. Once complete, our experienced installers will make sure your system is operational in your facility and our team will continue to protect your equipment for its entire life cycle with our inspection and maintenance services. From start to finish, we design, build, inspect, and maintain.

- Wall mounted jib crane

- Workstation bridge cranes

- Inspection and maintenance services

- Monorail systems for straight line movement

- Overhead crane with hoists for large loads

- Underhung wire rope hoist

- Crane installations meet all applicable standards and regulations

PROJECTS

Improving Safety and Productivity for Hammond Manufacturing

One of our customers recently purchased a brand new laser cutting machine that increased production while reducing the footprint in their facility. But there was a problem.

Maintenance Access Stand (Lifter)

Projects Maintenance Access Stand (Lifter) CHALLENGES Tight workspace Height adjustability Safe maintenance access Factory floor navigation SOLUTION A custom maintenance access stand was designed and

Pneumatic Material Handling Device

Designed and fabricated for a local manufacturing facility, this Vacuum Pneumatic Material Handling Device provides a safe ergonomic solution for lifting sheets of metal weighing up to 300 pounds.

Custom Sheet Lifter

Our team at Liftsafe engineered this electric powered telescoping sheet lifter for a valued client. The sheet lifter comes equipped with adjustable lifting fingers, worm and worm gear to prevent backlash, and a slip clutch torque limiter to prevent damaging the gears during operation.

Related Products

iNSPECTIONS

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

INDUSTRIAL CRANES & HOISTS

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

ENGINEERING SERVICES

Turnkey solutions with in-house engineering, design, and project management expertise.