Hooks and Spreader Bars

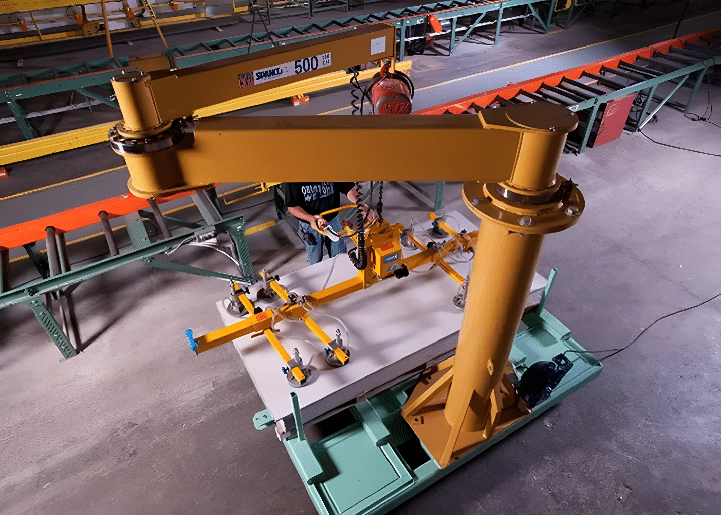

Hooks, tongs and spreader bars allow users to attach loads at multiple points or create a mechanism for balancing heavy and/or awkward loads for safe lifting. With over 25 years of experience building custom material handling devices for multiple sectors (Manufacturing and Automotive, Food and Beverage, Pharmaceutical, Concrete and Steel manufacturing to name a few), we can design, engineer, build, install, and service custom systems designed with your specific application in mind backed by our in-house team of Professional Engineers.

With our complete design, engineering, fabrication, and installation teams, we are able to rigorously test and refine our systems in order to create solutions for whatever material handling problem you are looking to solve.

Talk to a specialist today

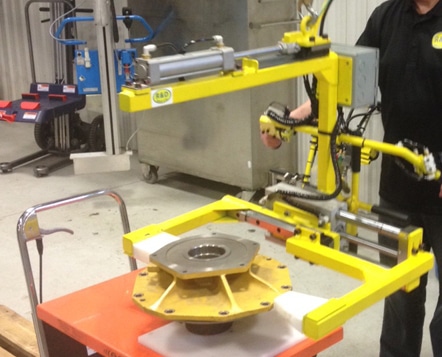

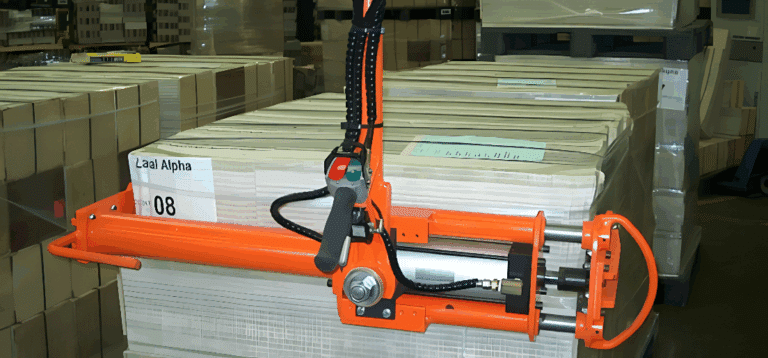

Hooks and Tongs

Custom hook lift assists can be manufactured to lift a number of heavy duty applications ranging from large vats to industrial roll cores.

Tongs are manufactured to create a “scissor” effect that clamps around different casting shapes in order to complete a lift

Designed to specific loading capacity.

Coil Hooks

Coil lifting hooks, or C-Hooks, are constructed in a range of forms to provide you flexibility and efficiency when managing your lifting tasks. The most typical applications for C-hooks are heavy-duty material handling, lifting, hauling, and/or stacking steel coils, sheet steel, and paper rolls.

Popular use cases:

- Efficient coil handling by taking into account your lifting capacity and various manufacturing requirements.

- Effortlessly and safely raise coils of sheet steel into production.

- Maneuver coils into small spaces to maximize production space use.

Designed to specific loading capacity.

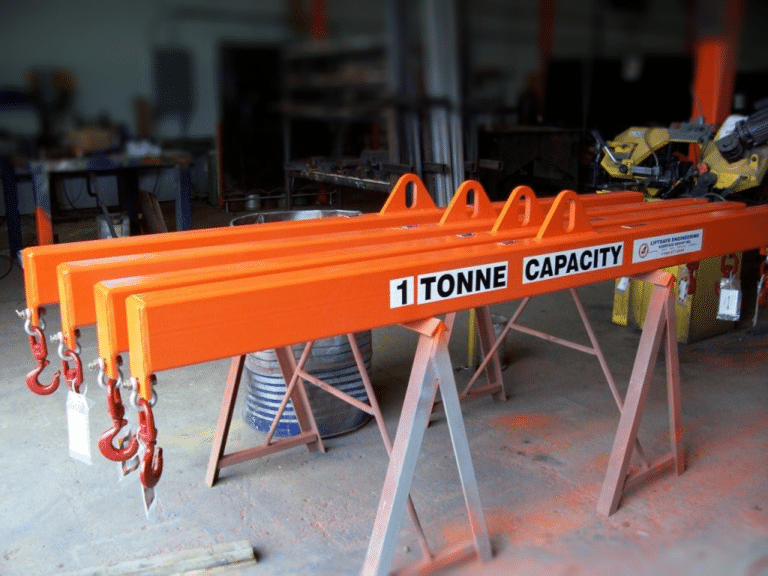

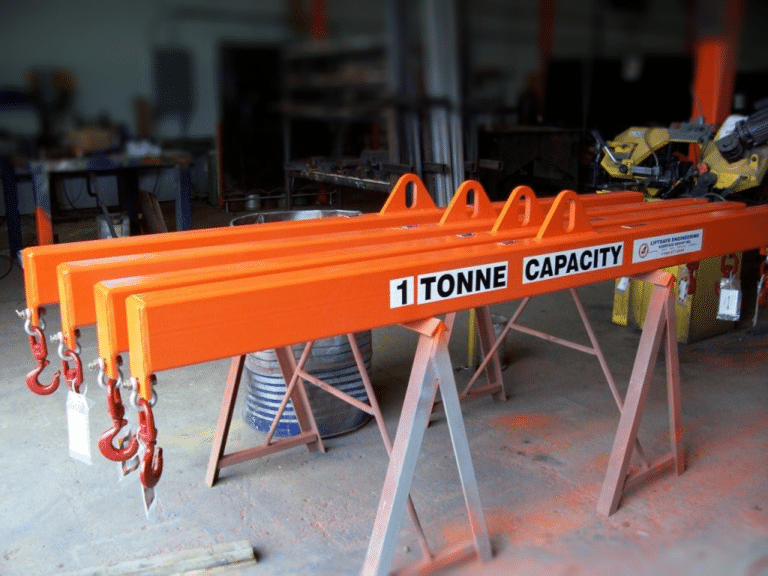

Spreader Bars

Despite their simplicity, spreader bars are a key piece of equipment for lifting. To achieve the lifting distance, they are made up of a long bar that holds wire rope slings apart. Lifting weights are converted into compressive forces in the spreader bar and tensile forces in the slings by the lifting spreader bar. This facilitates the lifting and transportation of large objects.

Spreader bars are ideal because they enable a single crane to lift items from several locations. It’s also simple to distribute the weight and provide the lift balance with these bars.

To accommodate a variety of lift spreads, you can also change the length of the shackles to change the length of the spreader bars.

Designed to specific loading capacity.

Key features

Safety First

Products engineered with uncompromising safety and quality to protect your people.

Innovation Driven

Custom and standard solutions built with creativity, reliability, and a customer-first focus.

In-House Expertise

Design, engineering, fabrication, installation, and inspection all under one roof.

Strategic Locations

30,000 sq. ft. of fabrication space across Ontario, serving clients nationwide.

Proven Experience

25+ years as a trusted partner to leading industries across North America.

Your Perfect Solution Awaits!

We can do it all

Liftsafe offers lifting systems and services for every aspect of your facility. Our specialists have the industry expertise to recommend the best system for upgrading and optimizing your space. Rely on our industry experts to do a walkthrough of your facility to find the right standard or custom lifting solution. From there our in-house engineering team will design your system to meet all regulatory standards which then gets manufactured by CWB qualified welders. Once complete, our experienced installers will make sure your system is operational in your facility and our team will continue to protect your equipment for its entire life cycle with our inspection and maintenance services. From start to finish, we design, build, inspect, and maintain.

- Wall mounted jib crane

- Workstation bridge cranes

- Inspection and maintenance services

- Monorail systems for straight line movement

- Overhead crane with hoists for large loads

- Underhung wire rope hoist

- Crane installations meet all applicable standards and regulations

PROJECTS

Aluminum Ladder install

We provide a complete variety of fixed rooftop access ladders that are custom manufactured to match your needs. Our ladders are guaranteed to meet or surpass industry standards.

Fixed access Ladder Install

Our crew has been designing, building, and installing fixed access ladders for over ten years. Our ladders are built to withstand typical loads and meet all safety standards.

Davit Safety System

Our customer required approved fall arrest points on their mezzanine so that their millwrights could repair overhead equipment safely.

Secure Access Ladder for Maintenance

We fabricated and installed this fixed access ladder for a company in Mississauga.

Related Products

iNSPECTIONS

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

INDUSTRIAL CRANES & HOISTS

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

ENGINEERING SERVICES

Turnkey solutions with in-house engineering, design, and project management expertise.