Spanco

ALU-TRACK® WORKSTATION BRIDGE CRANES & RUNWAYS

Spanco

ALU-TRACK® WORKSTATION BRIDGE CRANES & RUNWAYS

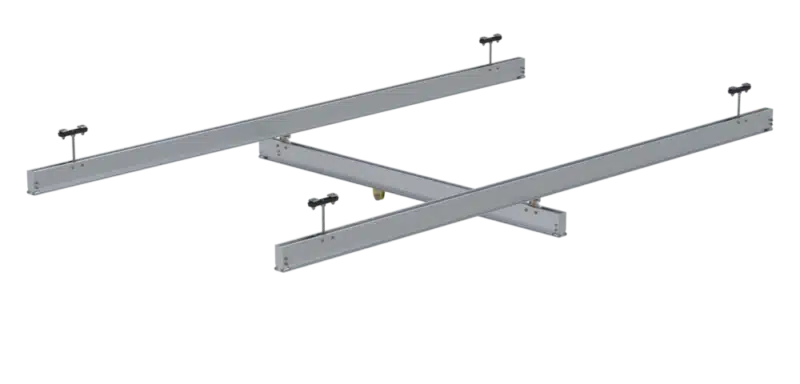

Spanco Alu-Track® Workstation Bridge Cranes and Runways is where agility meets durability in the realm of material handling. Crafted from high-strength 6061-T6 aluminum alloy, these systems redefine crane performance with lightweight construction, unmatched durability, and a maintenance-free design. With capacities ranging from 250 to 1,000 lbs, Alu-Track® provides a versatile solution for various applications, including workstation bridge cranes and monorail cranes.

Spanco Alu-Track® sets the benchmark for lightweight crane performance. The extruded high-strength aluminum alloy ensures durability, making it the ideal choice for applications requiring agility and resilience. Its non-corroding properties make it suitable for a range of environments, including clean rooms, refrigerated areas, and moisture-laden settings.

Alu-Track’s aluminum enclosed tracks significantly reduce the overall system weight, enhancing the ease of movement for the bridge. Particularly beneficial for Ceiling-Mounted Workstation Bridge Cranes, Alu-Track systems alleviate strain on building support structures, providing a solution that’s both efficient and cost-effective.

- Applications: Workstation bridge cranes and monorail cranes

- Material: extruding hight-strength 6061-T6 aluminum alloy

- Capacities: 250 lbs., 500 lbs., or 1000 lbs.

- Bridge Span: up to 17 ft., dependent on capacity chosen

Spanco

Alu-Track® Workstation

Bridge Cranes and Runways

Specifications

| Type | Track Applications | Capacity | Bridge Length | Runway Support Centers | Runway Length | Height |

|---|---|---|---|---|---|---|

| Aluminum Ceiling-Mounted | Workstation bridge cranes & runways (including monorails) | 250 lbs. to 1,000 lbs. | 17 ft. standard; dependent on load capacity | 15 ft. standard; dependent on load capacity | Unlimited with splicing; 30 ft. without splicing | Determined by application; lowest as practical to minimize trolley resistance |

Regulations

Each of these systems meet the standards laid out in the AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.6 and CMAA 74.

Resources

Hoists

Liftsafe Engineering and Service Group carries top of the line hoists such as GH, Kito and Stahl.

Article

SWL/WLL/MRC – What do these abbreviations stand for and when should they be used?

Inspections

Periodic inspections based on crane use (see CSA B167-16), done by accredited inspectors is required by law.

GH Hoist Catalogue

lorem ipsum

Article

lorem ipsum

Case Study

lorem ipsum

Your Perfect Solution Awaits!

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

Polytainers Overhead Bridge Crane Case Study

Our main concern was being able to safely and efficiently maneuver large molds and dies in and out of injection molding and thermoforming machines.

Crane Inspections and Maintenance

From design to implementation, we offer inspection, maintenance and repair services that span the entire life cycle of your lifting and material handling equipment.

We design, build, inspect and maintain.

GH Cranes & Hoists

Liftsafe is a leading supplier of GH products in Canada, offering premier industrial lifting equipment.

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.