GH Top Running Electric Hoists

GH Top Running Electric Hoists can be configured to fit multiple top running crane configurations. Top running crane configurations are advantageous for long bridge spans, offering greater hook height and headroom for lifts. These cranes feature a fixed rail or track system atop each runway beam, allowing the bridge and hoist to move along. They can be single or double girder designs, typically utilizing a top-running trolley and hoist. Top-running cranes have versatile capacities, ranging from small to extremely heavy loads, supported by building structures or runway columns. A top-running crane allows the greatest lifting height, as the hoist rides on top of the runway beam, providing increased lifting height.

Single Girder Overhead Crane: The most popular for its simplicity and cost-effectiveness. Involves a single bridge traveling along adjacent runways, with the hoist moving horizontally. Offers maximum facility coverage, a load capacity of up to 20 tons, and quick setup at a relatively low cost.

Double Girder Overhead Crane: Ideal for heavy-duty lifting. Features two parallel bridges traveling along adjacent runways, with the trolley and hoist moving above the bridge for maximum hook height. Recommended for applications exceeding 20 tons or special lift height requirements. While setup costs may be higher, the double girder crane proves to be a valuable long-term investment in efficiency and cost savings.

The following GH hoists are configured for top-running cranes in multiple configurations.

Single Girder Top Running Electric Hoists

Low-headroom hoists

Low-headroom hoists are perfect for using in the small under-beam space in single-girder cranes.

Choose between flat or angled wheels to suit your bottom flanges and running profile, to improve performance and increase the life of your hoist.

Standard-headroom hoists

Our standard-headroom hoists are the perfect solution when the amount of space under your single-girder crane is not critical, or when you are moving loads between halls.

This configuration is suitable for 1/1 and 2/2 reeving hoists.

Choose between flat or angled wheels to suit your bottom flanges and running profile, to improve performance and increase the life of your hoist.

Standard-headroom hoists ready for curves

This hoist is designed for applications that involve moving loads along curved paths and changes in direction.

Choose between flat or angled wheels to suit your bottom flanges and running profile, to improve performance and increase the life of your hoist.

Double Girder Top Running Electric Hoists

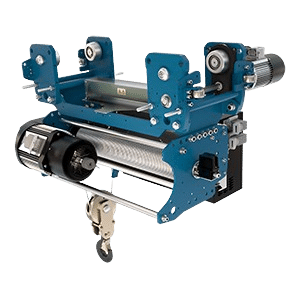

Compact hoists

GH compact hoists are the most compact double-girder hoists available today. Their simple yet robust design makes them ideal for multiple applications that require a compact hoist.

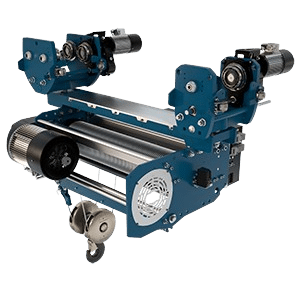

Hoists on end trucks

GH manufacturers a number of hoists that are designed for trolleys with two hoists, rotating trolleys, and other applications that involve end trucks.

Available options include a manual brake release, weighing system and additional safety brake.

GH Top Running Electric Hoist Specifications

| Features | Benefits |

|---|---|

| ALE-100/TN Electronic Limiter | Overload, loose wire rope, and motor overheating control. |

| Record and Control Function | Comprehensive data recording and analysis. |

| Anti-Collision Photocells | Enhanced safety by preventing collisions. |

| Weighing Display | Accurate weight measurement for precise operations. |

| Safety Brake on Drum | Ensures secure braking for enhanced safety. |

| Hook Blocking System | Prevents unwanted movement for increased safety. |

| Remote Control | Convenient operation from a distance. |

| Data Displayed on Remote Control | Easy access to critical data during operation. |

| Data Displayed on Radio Remote Control | Convenient data monitoring with radio remote control. |

| Load Control Hoist Versions | Improved control over hoisting operations. |

| Frequency Inverter | Enhanced control and energy efficiency. |

| Electronic Load Limit Device (ALE-100/TN) | Precise load management and safety. |

| Radio Remote Control with Display | Convenient remote operation with real-time data display. |

Regulations

Each of these systems meet the standards laid out in the AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.6 and CMAA 74.

Resources

Hoists

Liftsafe Engineering and Service Group carries top of the line hoists such as GH, Kito and Stahl.

Article

SWL/WLL/MRC – What do these abbreviations stand for and when should they be used?

Inspections

Periodic inspections based on crane use (see CSA B167-16), done by accredited inspectors is required by law.

With the GH Core Box you will improve your crane’s performance with unparalleled control using our electronic load limiter, efficient hoist motor management, and prevention of over-temperature incidents. Gain valuable insights into your crane’s operations through comprehensive monitoring, including detailed operational data and incident logs. The Core Box goes beyond conventional monitoring by communicating parameters via a cellular network to GH Realtime, our proprietary data platform. Access advanced usage and maintenance services through the GH CRANES Customer Portal, providing real-time information on your crane’s operation.

How It Works:

Data Reception: Core Box gathers data from load cells, VFDs, and thermal sensors of the motors.

Processing Power: Core Box efficiently processes and records operating parameters and detected errors for insightful analysis.

Data Transmission: Transmit lifted load and SWP data to displays or radio controls, providing real-time information.

Connectivity Beyond: Utilize cellular network connectivity to seamlessly communicate with GH CRANES’ proprietary platform for advanced services.

Advantages:

All-in-One Integration: Enjoy the convenience of having Control, Monitoring, and Connectivity seamlessly integrated into a single device.

Accessory Connectivity: Connect to accessories such as Displays and Radio Controls for continuous monitoring of crucial data like Lifted Loads and Safe Working Period (SWP).

Non-Intrusive Connectivity: Communicate via 3G/4G networks, ensuring that the Core Box doesn’t interfere with your internal network.

Universal Compatibility: Retrofit Core Box to other crane brands, enabling monitoring and SWP calculation without disrupting their existing operation.

Your Perfect Solution Awaits!

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

Polytainers Overhead Bridge Crane Case Study

Our main concern was being able to safely and efficiently maneuver large molds and dies in and out of injection molding and thermoforming machines.

Crane Inspections and Maintenance

From design to implementation, we offer inspection, maintenance and repair services that span the entire life cycle of your lifting and material handling equipment.

We design, build, inspect and maintain.

GH Cranes & Hoists

Liftsafe is a leading supplier of GH products in Canada, offering premier industrial lifting equipment.

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.