Reverse Engineering

Regulations to consider

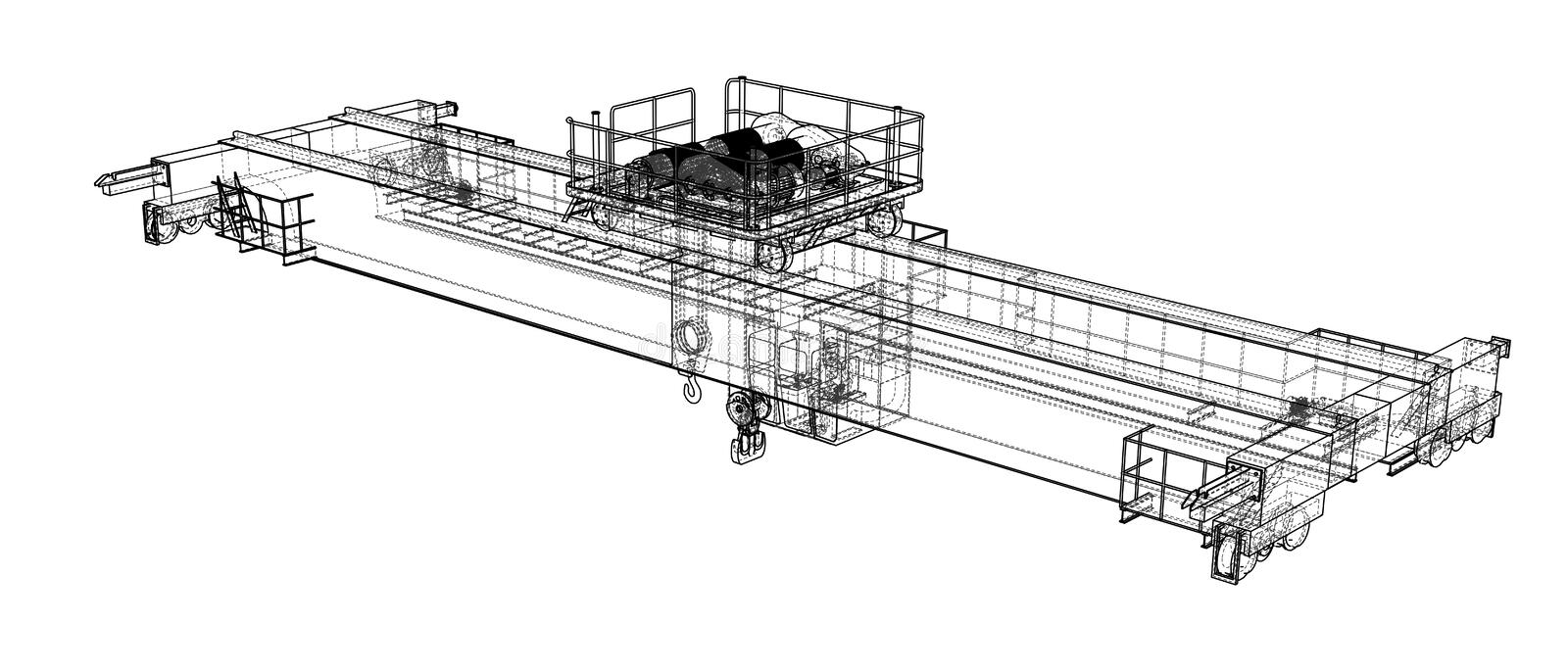

Next Hydrogen Large Industrial Gantry Crane

Our team performed the design, fabrication, welding and painting operations for their new, large custom gantry crane at our facility. The installation helped to improve our clients’ facility operations.

Outdoor maintenance travelers

A recent large-scale project has our team installing replacement “Maintenance Travellers” for the underside of a suspension bridge over the St. Lawrence river between Ontario and New York.

Custom Transfer Cart

One of our customers recently purchased a brand new laser cutting machine that increased production while reducing the footprint in their facility. But there was a problem.

- CWB Certified Welders (Steel and Aluminum)

- CWB certified for welding of Steel (CSA Standard W47.1, Division 2)

- CWB certified for welding of Aluminum (CSA Standard W47.2, Division 2)

- Professional Engineers Ontario

- CLAC

Custom Engineering

Concept

Taking a collaborative approach, we work with our clients to investigate all of the requirements of a project from a productive, environmental, usage and safety capacity. Then we use this information to inform our in-house design team.

Design

Our in-house design team combines their years of collective experience in manufacturing design and engineering with technical software and regulatory knowledge to design a solution for the project at hand to be sent for approval from our in-house engineering team.

Approval

Our in-house engineering team makes adjustments to make sure the initial design meets or exceeds all capacity, usage, environmental, safety and regulatory criteria and approves the project for fabrication.

Fabrication

Our team of CWB Certified welders brings the approved design concepts created by our design and engineering teams to life in our 30,000 sq ft fabrication facility.

Inspection

Once a project has completed the fabrication stage, it is inspected and tested to ensure all capacity, usage, environmental, safety and regulatory criteria are met or exceeded.

Installation

Once final inspection is completed, your project is ready for the installation phase, which includes physical installation, implementation of in-site training, adjustments (as needed), a Prestart Health and Safety Review, exemption letters, engineering sign-offs, and electrification according to CSA C22 standards (if applicable).

Request a Quote

Related Products

Equipment Repairs

At Liftsafe Engineering & Service Group, equipment repairs and service are where we shine. Our vision and goal is simple: to get you up and running as quickly, safely, and cost-efficiently as possible.

Engineering Design

From the cranes that can add capacity to your facility to the ergonomic material handling device that can eliminate work-related repetitive strain injuries: Liftsafe brings together our design engineering team and cutting-edge design software to deliver turnkey solutions for our clients in multiple industries.

Inspections

Helping business owners and plant managers protect their business and employees from a safety and regulatory standpoint by providing turnkey inspection services that ensure your equipment is certified “safe” and documented.

About Liftsafe Engineering & Service Group

Resource Center

Customer Service

Request a quote

We offer a huge selection of products and quick quotes for what you’re looking for.

Have questions?

Give us a call. Our friendly customer service staff are on hand and ready to help you.