Hazardous Environment Hoists

Specialized hazardous environment hoists are indispensable for carrying out tasks safely and ensuring compliance with laws and standards. Ensuring safety in demanding and risky settings is paramount for the seamless functioning of various businesses and sectors. These environments can potentially endanger both materials and personnel. Whether it’s within a chemical plant, petrochemical facility, or steel-making plant, hazardous conditions are present.

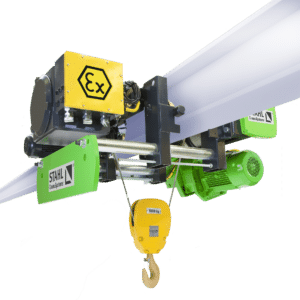

SH Ex Wire Rope Hoist

The STAHL Explosion-proof Ex wire rope hoists and SHW 8 Ex winches stand out as top-tier safety technology in the market, catering to a range of industries including chemical, petrochemical, pharmaceutical, food processing, power supply, shipbuilding, offshore, and LNG. These programs are built upon the solid foundation of our standard wire rope hoists and SHW winches, ensuring consistency and reliability. Compliance with rigorous ATEX directives and IECEx regulations for mechanical and electrical explosion protection is guaranteed.

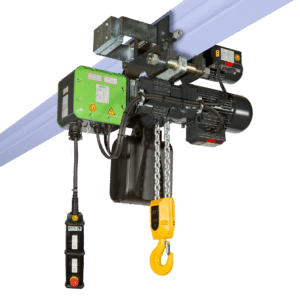

ST Ex Chain Hoist

The STAHL Explosion-proof ST Ex chain hoists represent cutting-edge safety technology, offering unparalleled protection for industries including chemical, petrochemical, pharmaceutical, food processing, power supply, shipbuilding, offshore, and LNG. Based on the modular ST chain hoist program, our ST Ex chain hoist program ensures reliability and consistency. With a safe working load range spanning from 250 kg to 6,300 kg for Zone 1 and Zone 21, and from 125 kg to 6,300 kg for Zone 22, these hoists are adaptable to various environments. Compliance with strict ATEX directives and IECEx regulations for mechanical and electrical explosion protection is guaranteed.

Lodestar Classic Clean Room

The CM Lodestar Classic Clean Room electric chain hoist provides performance tailored for clean rooms, from basic wipe-down to full wash-down setups. The Lodestar ensures reliability and consistency across diverse tasks, with features like stainless steel load chains and sealed, weather-proof construction. Choose from various capacities and customizations to meet your specific needs.

Hazardous Environment Hoist Specifications

| Specification | ST Ex Chain Hoist | SH Ex Wire Rope Hoist | CM Lodestar Electric Chain Hoist |

| Industry | Chemical, petrochemical, pharmaceutical, food processing, power supply, shipbuilding, offshore, LNG | Chemical, petrochemical, pharmaceutical, food processing, power supply, shipbuilding, offshore, LNG | Various industrial applications |

| Explosion Protection | Full high-quality explosion protection | Full high-quality explosion protection | Full high-quality explosion protection |

| Gear Box Lubrication | Lifetime grease-lubricated | Lifetime grease-lubricated | Lifetime grease-lubricated |

| Motor | Heavy duty | Heavy duty | Heavy duty rated motors |

| Optional Features | Custom | Custom | Double DC Brake, AC Electrical Brake, Variable speed drive (VFD), Rotatable limit switch, Black phosphate or stainless steel load chain, Metal and stainless steel chain containers. |

| Clean Room Adaptability | yes | yes | yes |

| Certification | ATEX, IECEx | ATEX, IECEx | CSA/US National Recognized Testing Laboratory (NRTL) |

| Additional Information | International specialist for explosion protection technology, Extensive range for various zones | International specialist for explosion-proof crane technology, Cable pull programs and winch program available | Ideal for high duty cycles and tough applications, Documented RoHS compliance, Shipped in boxes made of recycled material |

Regulations

Each of these systems meet the standards laid out in the AISC Steel Construction Manual, OSHA 1910.179, ANSI B30.11, AWS D1.1/D1.6 and CMAA 74. For hazardous environment equipment, systems also meet the regulatory requirement for the EU (ATEX), the certification requirement IECEx and/or CSA/US National Recognized Testing Laboratory (NRTL) requirements.

Resources

Hoists

Liftsafe Engineering and Service Group carries top of the line hoists such as GH, Kito and Stahl.

Article

SWL/WLL/MRC – What do these abbreviations stand for and when should they be used?

Inspections

Periodic inspections based on crane use (see CSA B167-16), done by accredited inspectors is required by law.

Your Perfect Solution Awaits!

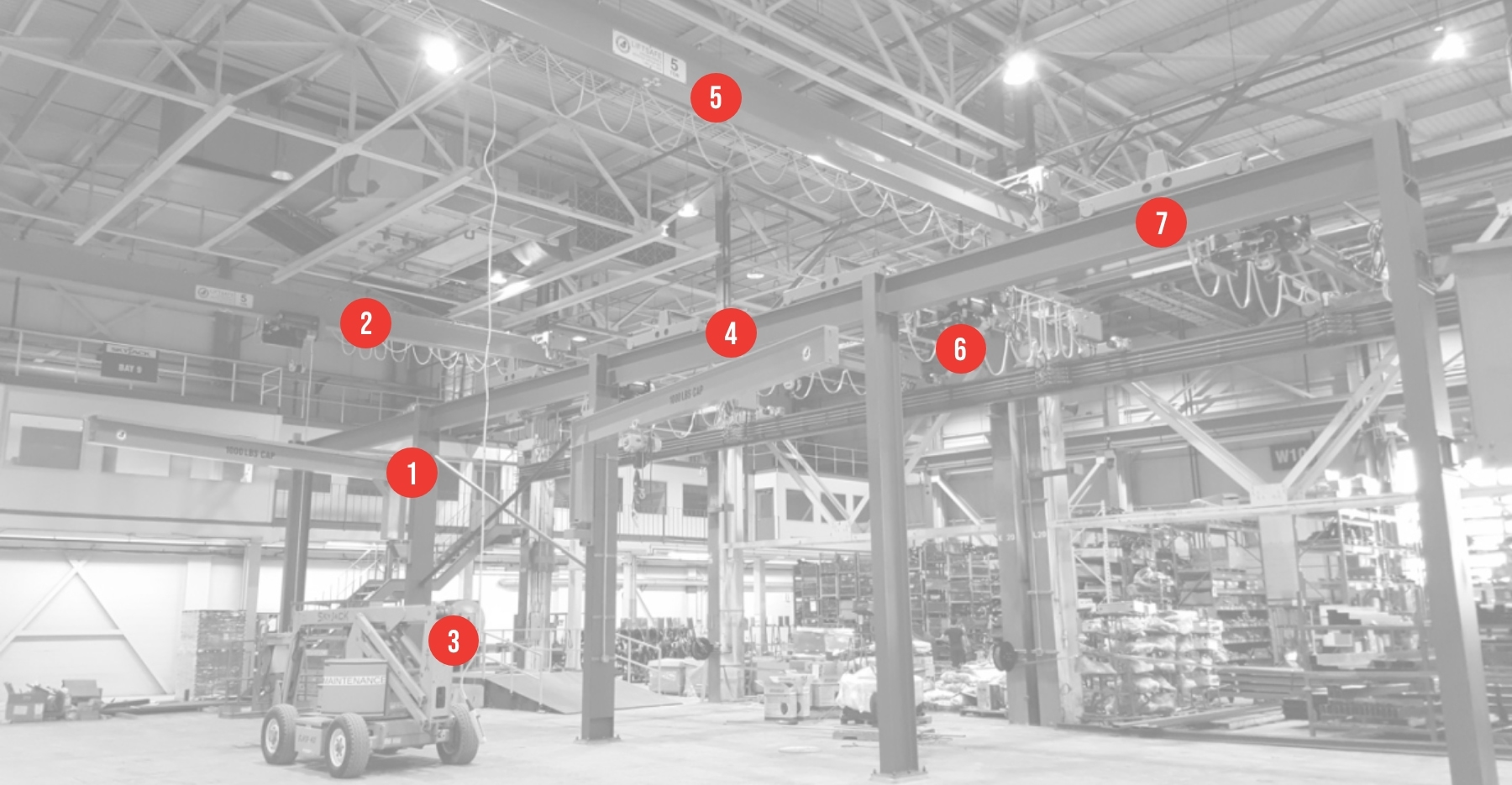

We can do it all

Liftsafe Engineering offers lifting systems and services for every aspect of your facility. Our specialists have the industry expertise to recommend the best system for upgrading and optimizing your space. Rely on our industry experts to do a walkthrough of your facility to find the right standard or custom lifting solution. From there our in-house engineering team will design your system to meet all regulatory standards which then gets manufactured by CWB qualified welders. Once complete our experienced installers will make sure your system is operational in your facility and our team will continue to protect your equipment for its entire life cycle with our inspection and maintenance services. From start to finish, we design, build, inspect, and maintain.

- Wall mounted jib crane

- Workstation bridge cranes

- Inspection and maintenance services

- Monorail systems for straight line movement

- Overhead crane with hoists for large loads

- Underhung wire rope hoist

- Crane installations meet all applicable standards and regulations

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

Polytainers Overhead Bridge Crane Case Study

Our main concern was being able to safely and efficiently maneuver large molds and dies in and out of injection molding and thermoforming machines.

Crane Inspections and Maintenance

From design to implementation, we offer inspection, maintenance and repair services that span the entire life cycle of your lifting and material handling equipment.

We design, build, inspect and maintain.

GH Cranes & Hoists

Liftsafe is a leading supplier of GH products in Canada, offering premier industrial lifting equipment.

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.