Hoists

Liftsafe Engineering is a leading Hoist supplier with over 25 years of experience manufacturing, installing, inspecting, and repairing crane and hoist systems. Working alongside our trusted suppliers, we combine expert service and parts to create both standard and custom systems that are not only reliable but affordable. Liftsafe Engineering offers a wide variety of hoists to suit your lifting and material handling needs. We offer a complete line of chain, wire rope, pneumatic, chain and lever hoists. Rely on our in-house engineering, design, fabrication, and installation team to deliver from our comprehensive list of hoist systems on the market. Liftsafe Engineering will be with you throughout every stage of your project build as a single source for manufacturing, installation, training, aftercare and regular service. CMAA and CSA compliant.

Need Guidance on Crane and Hoist Compliance?

Our detailed guide on CSA B167-16 provides crucial insights into crane and hoist regulations. Essential reading for anyone responsible for compliance and safety. Check out the full guide now.

Hoist inspection and maintenance is available 24/7 through our online Customer Portal.

AIR Chain Hoists

Pneumatic (air) chain hoists are perfect for environments without electricity or in hazardous conditions. They are also well-suited for applications requiring high lifting speeds. Liftsafe Engineering provides a variety of pneumatic chain hoists in different sizes and configurations, ensuring safe and efficient heavy load transportation. These hoists, powered by air pressure, offer a reliable solution for specialized jobs, combining safety and speed.

Capacity: 1/4 to 6 tonnes

AIR Wire Rope Hoists

Choose from a diverse range of air wire rope hoists tailored for construction, maintenance, and industrial applications. Our industrial duty hoists, designed for heavy-duty lifting in electricity-unavailable or hazardous environments, ensure unmatched durability. Count on smooth lifting in high-usage scenarios. Our specialists are ready to assist in finding the ideal hoist for your facility or crafting a customized solution.

Designed to specific loading capacity.

ELECTRIC Chain Hoists

Liftsafe Engineering offers electric chain hoists designed for flexibility and durability in lifting. Electric hoists are designed to lift and lower objects in a vertical plane. Compact headroom, hook suspension, and a range of other features make the hoist easily adjustable for your specific workstation needs. Use these electric chain hoists on an overhead crane, a workstation crane, or with a jib crane. Liftsafe offers various versatile chain hoist options making us an ideal solution for many lifting applications.

Capacity: 1/8 to 20 tonnes

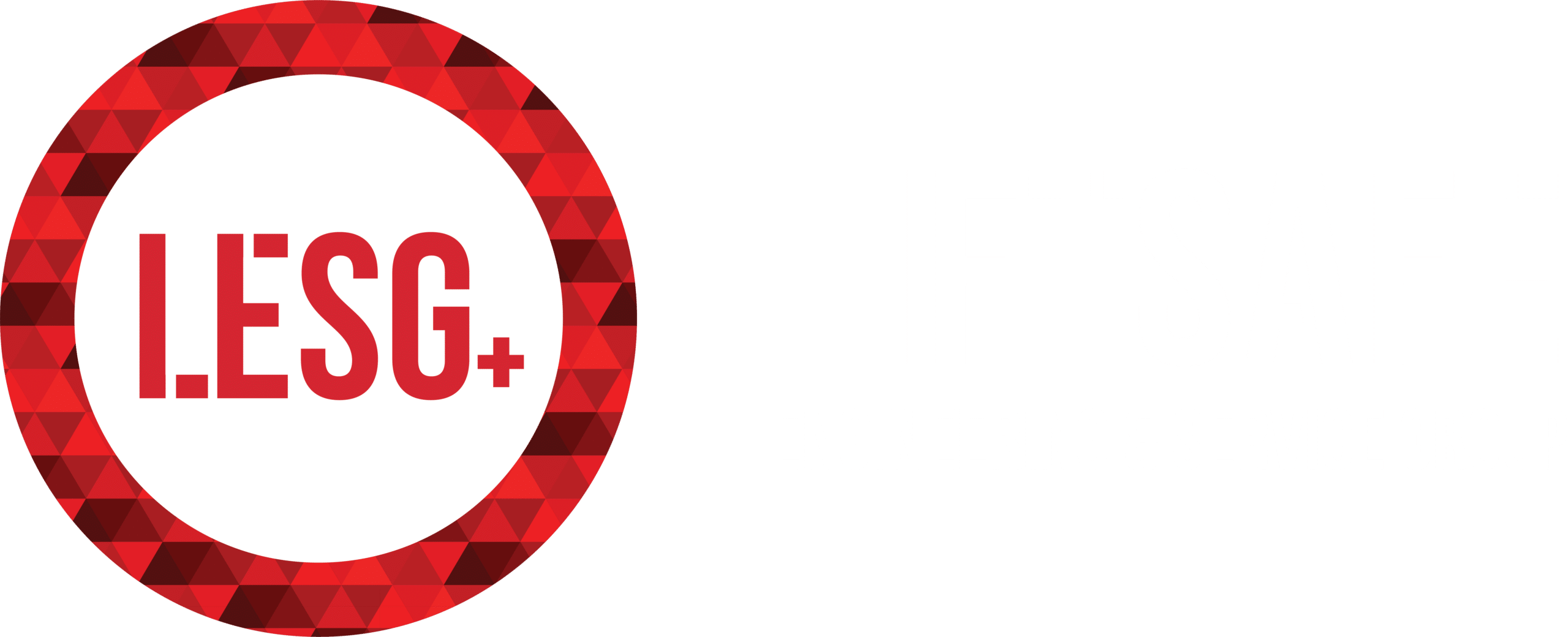

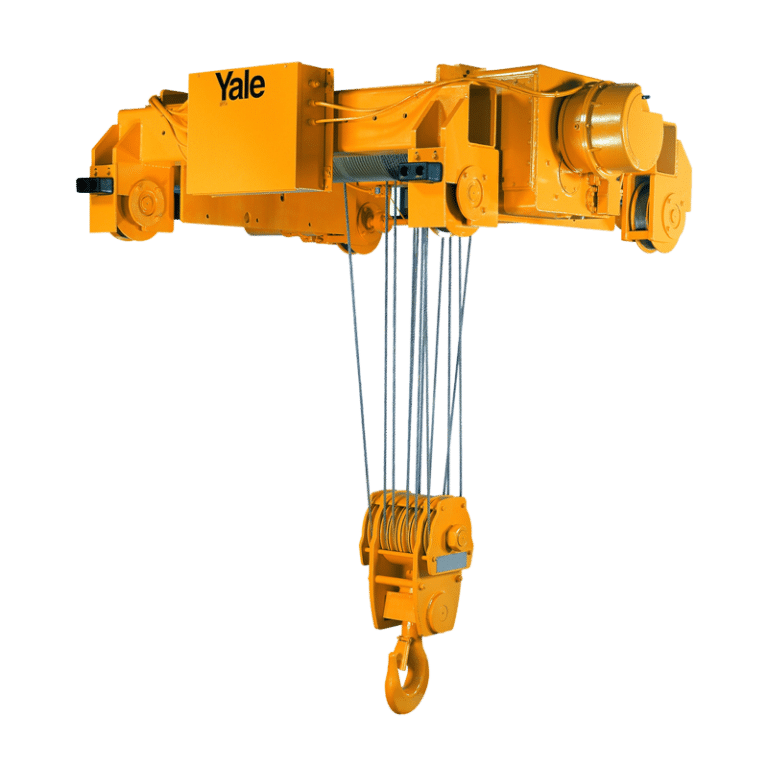

ELECTRIC Wire Rope Hoists

Our wire rope hoists, feature diverse brands, capacities, lifts, and customizable options. These hoists, designed for construction, maintenance, and industrial applications, stand out for their exceptional durability and reliability. Particularly effective in higher capacity material handling environments, electric wire rope hoists provide greater flexibility for specialized applications, further enhancing their versatility in various scenarios.

Designed to specific loading capacity.

ELECTRIC Winches

Liftsafe Engineering & Service Group provides open winch systems designed for horizontal load pulling over slightly inclined or level surfaces. While winches handle horizontal pulling, hoists lift loads vertically over steeper inclines. Tailored to your facility and equipment applications, an open winch can be an excellent lifting solution. Specializing in industrial electric winches suitable for towing automobiles and heavy equipment, our specialists can guide you in selecting the ideal open winch system, considering factors such as environment, task, facility space, and equipment transportation needs.

Designed to specific loading capacity.

MANUAL Hand Chain Hoists

Liftsafe Engineering offers a diverse selection of Hand chain hoists, also known as chain fall hoists, from various manufacturers. Ideal for construction, maintenance, and industrial applications, these hoists provide a reliable and efficient solution in facilities where electricity is impractical or unavailable, such as portable gantry or jib cranes. These hoists offer unmatched durability and reliability, and specialized options are available for specific needs, including low headroom, explosion-proof environments, or cleanrooms.

Capacity: 1/2 to 50 tonnes

MANUAL Lever Hoists

Our compact, portable and highly durable lever hoists pull, lift and position materials with ease. Lever hoists are often referred to as ratchet hoists and allow the operator to move a load through ratcheting movements. These hoists are commonly used for stretching, pulling, tightening or positioning loads in select overhead lifting applications. Lever hoists rely on manual operation to lift or lower loads and fall into typically two main categories, cable/rope hoist or chain hoists.

Capacity: 1/4 to 9 tonnes

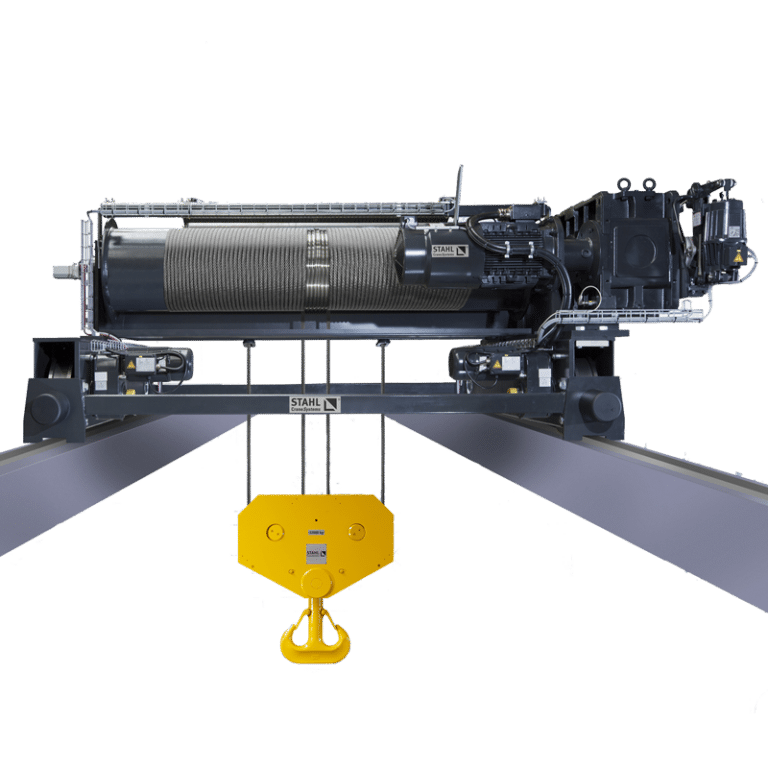

Hazardous Environment Hoists

Specialized hazardous environment hoists are indispensable for carrying out tasks safely and ensuring compliance with laws and standards. Ensuring safety in demanding and risky settings is paramount for the seamless functioning of various businesses and sectors. These environments can potentially endanger both materials and personnel. Whether it’s within a chemical plant, petrochemical facility, or steel-making plant, hazardous conditions are present.

Capacity: Build to Specifications Required

Your Perfect Solution Awaits!

We can do it all

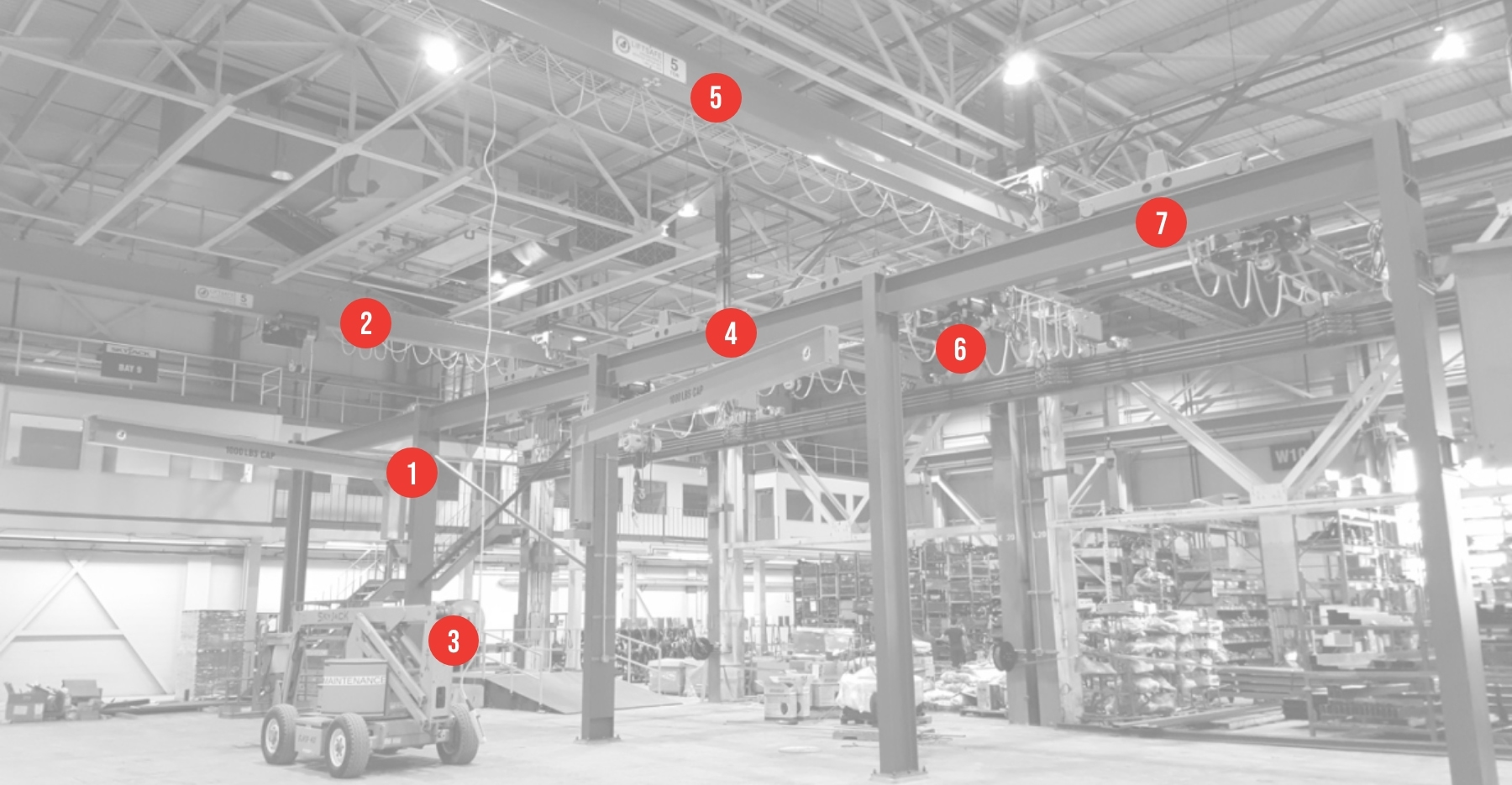

Liftsafe Engineering offers lifting systems and services for every aspect of your facility. Our specialists have the industry expertise to recommend the best system for upgrading and optimizing your space. Rely on our industry experts to do a walkthrough of your facility to find the right standard or custom lifting solution. From there our in-house engineering team will design your system to meet all regulatory standards which then gets manufactured by CWB qualified welders. Once complete our experienced installers will make sure your system is operational in your facility and our team will continue to protect your equipment for its entire life cycle with our inspection and maintenance services. From start to finish, we design, build, inspect, and maintain.

- Wall mounted jib crane

- Workstation bridge cranes

- Inspection and maintenance services

- Monorail systems for straight line movement

- Overhead crane with hoists for large loads

- Underhung wire rope hoist

- Crane installations meet all applicable standards and regulations

Playlist

2:48

1:45

1:47

1:44

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

Polytainers Overhead Bridge Crane Case Study

Our main concern was being able to safely and efficiently maneuver large molds and dies in and out of injection molding and thermoforming machines.

Crane Inspections and Maintenance

From design to implementation, we offer inspection, maintenance and repair services that span the entire life cycle of your lifting and material handling equipment.

We design, build, inspect and maintain.

GH Cranes & Hoists

Liftsafe is a leading supplier of GH products in Canada, offering premier industrial lifting equipment.

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.