GH Wire Rope Hoists: Elevating Performance

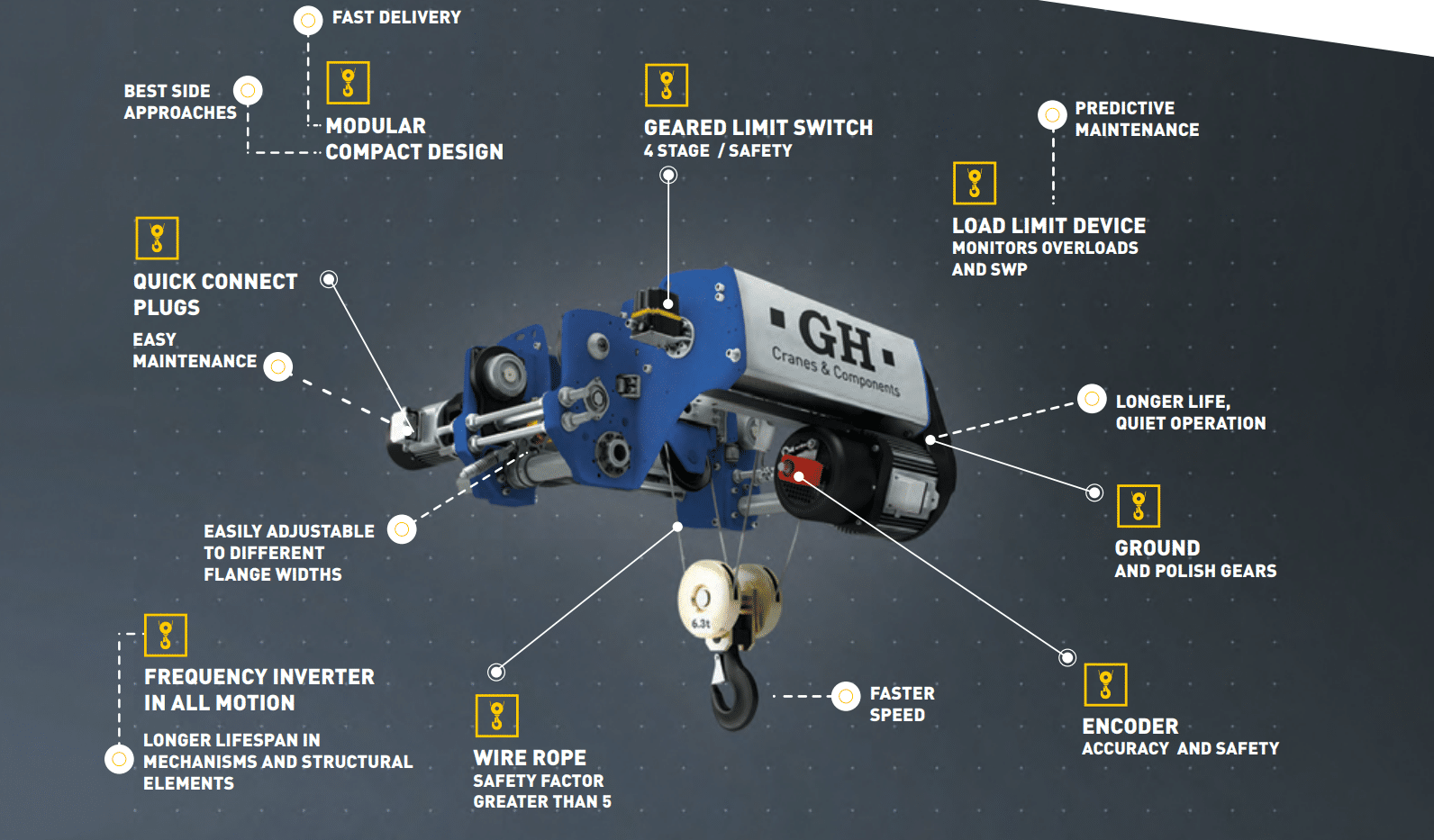

GH wire rope hoists, engineered for excellence, cater to a variety of applications including bridge, gantry, and semi-gantry cranes, adapting seamlessly to single or double girder setups with lifting capacities ranging from 800 Kg to an impressive 100 tons. Built with rugged and compact construction, these hoists ensure longevity and reliability, facilitated by modular construction that minimizes downtime during maintenance.

GH hoists offer a wide range of hook paths, lifting speeds, and adherence to working group FEM/ISO standards, allowing you to tailor the hoist to the specific demands of starts per hour and duty cycles. Equipped with a standard control system and real-time monitoring of the Safe Operation Period, GH hoists allow users to perform preventive maintenance, enhancing overall safety and operational efficiency. The hoists’ performance is rooted in principles of reliability, security, durability, and cost-effectiveness, all together in a compact design that ensures perfect balance for a seamless lifting experience.

Flexible

GH wire rope hoists are perfect for overhead, gantry, and semi-gantry cranes, adapting effortlessly to single- and double-girder applications. With lifting capacities ranging from 800 kg to 100 tons, our hoists are designed to meet diverse needs.

Reliable

Rugged and compact, GH hoists are built to last, employing modular construction for extended life and easy maintenance. Trust in the reliability of GH hoists for consistent, high-performance lifting.

Practical

GH hoists offer practical solutions with a variety of cable strands, enabling a wide range of hook paths and lifting speeds. Customize your hoist based on the demands of starts per hour and duty cycles, ensuring optimal efficiency for the loads being lifted.

Select your crane configuration

Overhead bridge cranes offer various configurations, with key considerations being the number of beams (single girder or double girder), support type (freestanding or building supported), and whether it operates as top-running or under-running. The choice between top-running and under-running depends on the building structure and lift operation space requirements. It’s crucial to thoroughly understand lifting task requirements and operational environment to select the appropriate system.

Hoists for top-running cranes

Top-running overhead cranes run on a fixed rail mounted on top of runway beams, allowing for single or double girder configurations. They offer advantages like no limiting capacity, increased lift height, and easy installation, making them suitable for handling both small and large loads.

Hoists for Under-Running cranes

Under-running overhead cranes, also known as underhung cranes, have a user-friendly design with wheels supported by the bottom flange of the runway beam. Typically set up as a single girder, they excel in wide bays, have a lighter design, lower costs, and allow for multiple crane installations.

Your Perfect Solution Awaits!

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

Polytainers Overhead Bridge Crane Case Study

Our main concern was being able to safely and efficiently maneuver large molds and dies in and out of injection molding and thermoforming machines.

Crane Inspections and Maintenance

From design to implementation, we offer inspection, maintenance and repair services that span the entire life cycle of your lifting and material handling equipment.

We design, build, inspect and maintain.

GH Cranes & Hoists

Liftsafe is a leading supplier of GH products in Canada, offering premier industrial lifting equipment.

Customer Portal

Our customer portal reporting system is designed to give you 24-hour access to your reports, certificates and inspections.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.