Balancers

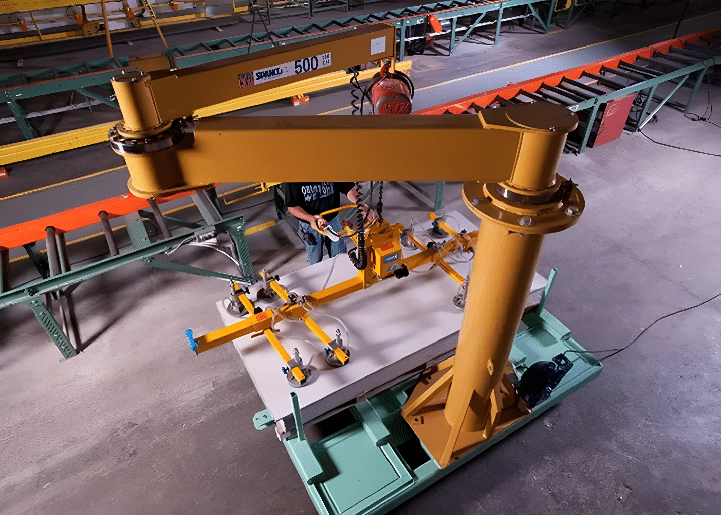

When conducting repetitive high-cycle jobs, balancers are a time and money-saving tool support device. They’re a low-cost and easy-to-use alternative to physical lifting. To provide a zero-gravity movement of equipment or materials, balancers use either springs or pneumatic air systems. When used in conjunction with jibs and workstation cranes, balancers efficiently handle all types of tools and parts at high speeds. Air balancers have a capacity range of 50 to 2000 pounds (22 to 909 kg).

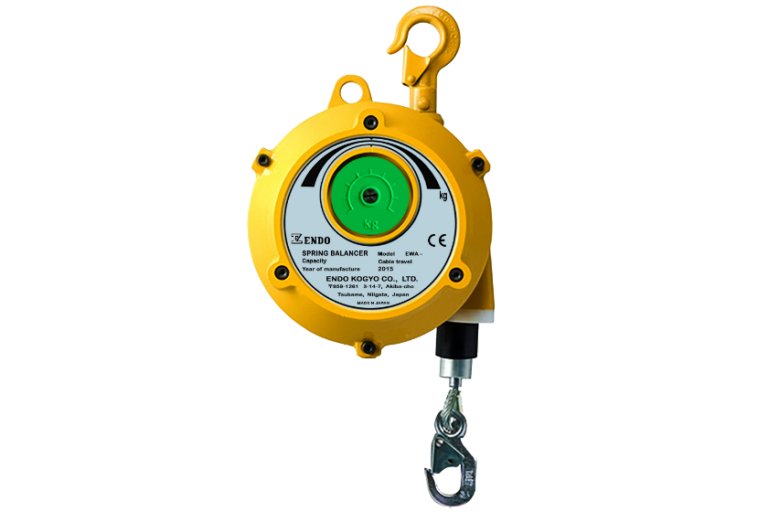

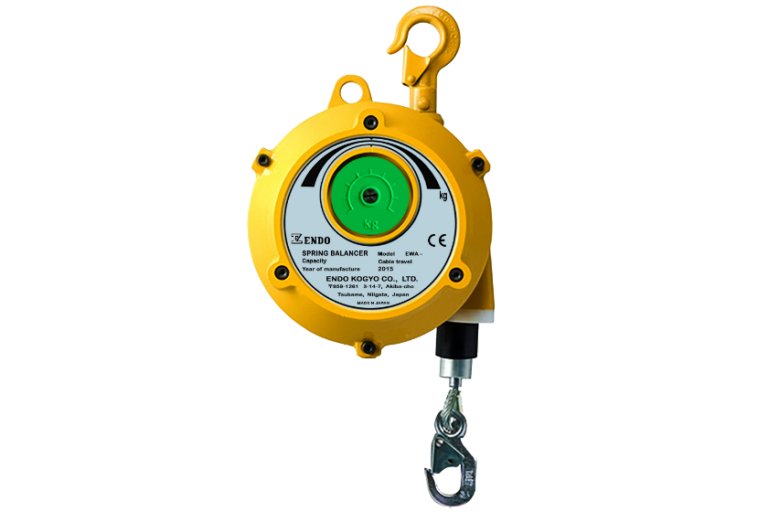

Mechanical spring balancers are suited for applications in which a fixed weight travels a limited vertical distance.

- Precise, strain-free positioning allows an operator to hands-free raise, lower, or shift heavy loads with virtually no resistance.

- Built-in safety features include overload protection and cable recoil breaks.

- Hook mount systems can be suspended with ease on a fixed system such as a jib crane or workstation crane.

- Rapid ROI through increased productivity.

- Reduced product damage.

- Reduce the possibility of operator injury.

- Enhances job performance.

- Eliminates potential regulatory fines for unsafe work.

Talk to a specialist today

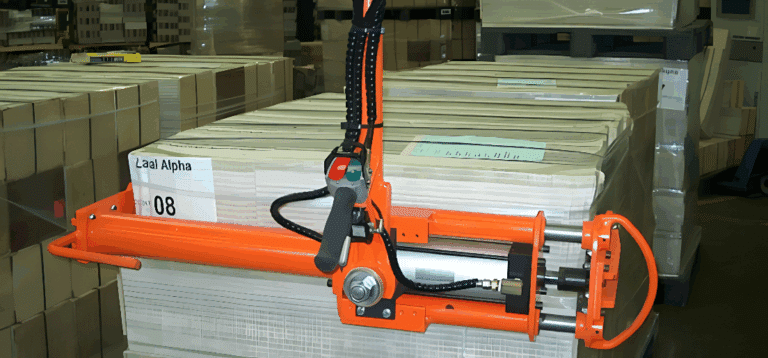

Air Balancers

Air Balancers are designed to assist in ergonomically transferring loads, up, down or balance “float” products safely and efficiently. Ideal for repetitive, high cycle tasks, Air Balancers are a cost-effective solution that will significantly increase production within your facility by leveraging a zero gravity movement of tools or materials.

Features such as the load float, allow users the ability to slowly and precisely place parts/materials into position. This is an ideal ergonomic solution for repetitive, high cycle tasks or precise “slower” applications.

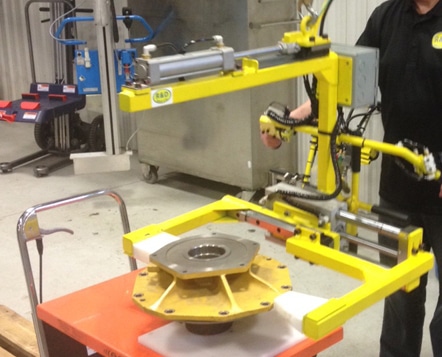

Intelligent Lifting Devices

Intelligent Lifting Devices combine the industry’s finest, mechanical balancing technology with the intelligence of precise, reliable electronic controls. This innovative combination provides operators with a safe, ergonomic, and highly flexible solution that can increase productivity and cost savings. To learn more about which type of Intelligent Lifting Devices will work with your equipment, contact one of our specialists for recommendations.

Mechanical (Spring) Balancer

Liftsafe offers gravity free mechanical spring balancers designed for intermediate and heavy-duty material handling applications. Tool balancers, load balancers, and spring balancers are the ideal tools to balance a constant load. These balancers permit fatigue-free working, even over prolonged periods of time.

Key features

Safety First

Products engineered with uncompromising safety and quality to protect your people.

Innovation Driven

Custom and standard solutions built with creativity, reliability, and a customer-first focus.

In-House Expertise

Design, engineering, fabrication, installation, and inspection all under one roof.

Strategic Locations

30,000 sq. ft. of fabrication space across Ontario, serving clients nationwide.

Proven Experience

25+ years as a trusted partner to leading industries across North America.

Your Perfect Solution Awaits!

We can do it all

Liftsafe offers lifting systems and services for every aspect of your facility. Our specialists have the industry expertise to recommend the best system for upgrading and optimizing your space. Rely on our industry experts to do a walkthrough of your facility to find the right standard or custom lifting solution. From there our in-house engineering team will design your system to meet all regulatory standards which then gets manufactured by CWB qualified welders. Once complete, our experienced installers will make sure your system is operational in your facility and our team will continue to protect your equipment for its entire life cycle with our inspection and maintenance services. From start to finish, we design, build, inspect, and maintain.

- Wall mounted jib crane

- Workstation bridge cranes

- Inspection and maintenance services

- Monorail systems for straight line movement

- Overhead crane with hoists for large loads

- Underhung wire rope hoist

- Crane installations meet all applicable standards and regulations

Hierarchy of ergonomics

Elimination

Where possible, it is always best to eliminate any possible hazards.

Engineering Controls

The goal of engineering controls is to improve the fit between the demands of work tasks and the capabilities of your workers safely.

Administrative controls

Administrative improvements, such as job rotation or alternating, can help reduce workers’ exposures to risk factors by limiting the amount of time workers spend on “problem jobs”.

Training

Training alone does not provide an ergonomic improvement. Instead, it should be used together with any workplace changes made. Workers need training and hands-on practice with new tools, equipment, or work practices to make sure they have the skills necessary to work safely.

Projects

Clamp Steel Sheet Lifter

Drastically reducing employee fatigue while increasing productivity, safety, and efficiency, we engineered this electric powered telescoping sheet lifter for a valued Ontario client.

Maintenance Access Stand

Our customer required a custom piece of equipment that could navigate the factory floor while also being adjustable in height, and we engineered this maintenance access stand.

CUSTOM TRANSFER CART

One of our customers recently purchased a brand new laser cutting machine that increased production while reducing the footprint in their facility. But there was a problem.

Custom Sheet lifter

Our team at Liftsafe engineered this electric powered telescoping sheet lifter for a valued client to reduce employee fatigue while increasing productivity and efficiency

Related Products

iNSPECTIONS

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

INDUSTRIAL CRANES & HOISTS

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

ENGINEERING SERVICES

Turnkey solutions with in-house engineering, design, and project management expertise.