Engineering Design

A large part of any health and safety program is to gather input from operators using the equipment on how to make processes more efficient in a safe way. Concepts and solutions often come from these conversations that either require an outside contractor to build or are built in house. Regardless of the solution, equipment is required by law to have certain conditions met. One of those conditions is often approval or supervision of the project by a professional engineer.

The in-house engineering team at Liftsafe works with our clients to design new solutions to your manufacturing processes or reverse engineer the solutions you created in-house for safety and regulatory compliance and provide the appropriate documentation.

- Overhead Bridge Cranes

- Jib Cranes

- Lifting Support Structures

- Spreader Beams and other Below-the-Hook Devices

- Forklift Attachments

- Structural Racking and Shelving

- Building Design

- Machine and Building Foundations

- Machine Guarding

- Below the Hook Devices

- Ergonomic Material Handling

Effective March 1, 2013, those responsible for professional engineering work in relation to production machinery or equipment must be licensed by Professional Engineers Ontario (PEO).

With the repeal of section 12(3)(a) of the Professional Engineers Act, individuals must now be licensed by PEO if they do any act within the practice of professional engineering on machinery or equipment used to produce products for their employer in their employer’s facility.

In 1984, when the exception was enacted, requirements existed for Ontario’s Ministry of Labour engineers to approve predevelopment reviews of proposed industrial processes and associated equipment. This requirement was replaced by Regulation 851 under the Occupational Health and Safety Act, which introduced the current requirement for industry to have professional engineers approve Pre-Start Health and Safety Reviews (PSRs) prior to the start-up of newly installed or altered production equipment or machinery.

Talk to a specialist today

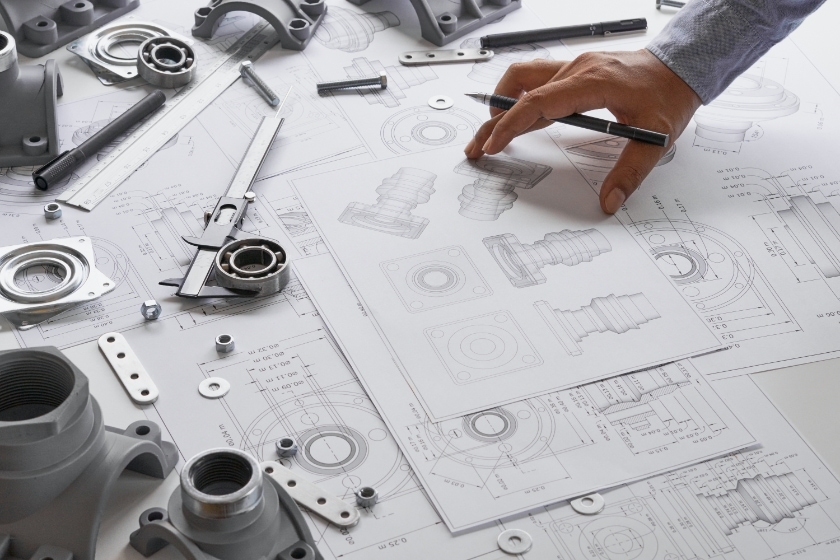

DESIGN ENGINEERING

From the cranes that can add capacity to your facility to the ergonomic material handling device that can eliminate work related repetitive strain injuries: Liftsafe brings together our design engineering team and cutting-edge design software to deliver turnkey solutions for our clients in multiple industries. We take a collaborative approach with our clients on each project, as we support them throughout the full project life-cycle, from concept, to detailed design and whole life support.

reverse engineering

Often lifting devices are made in-house or have no proper documentation for the item’s intended lifting capacity. The Liftsafe team can work with your team to reverse engineer your solution in order to provide you with proper documentation ensuring the item is safe to use and meets the requirements of its intended capacity. Using proper safety factors to ensure the device can easily handle the load, we are able to test and determine whether it meets its intended purpose or if it is underrated. If the device is underrated we can provide details for upgrades to meet the capacities required.

Key features

Safety First

Products engineered with uncompromising safety and quality to protect your people.

Innovation Driven

Custom and standard solutions built with creativity, reliability, and a customer-first focus.

In-House Expertise

Design, engineering, fabrication, installation, and inspection all under one roof.

Strategic Locations

30,000 sq. ft. of fabrication space across Ontario, serving clients nationwide.

Proven Experience

25+ years as a trusted partner to leading industries across North America.

Your Perfect Solution Awaits!

Regulations in Canada

| Regulation |

|---|

| CWB Certified Welders (Steel and Aluminum) |

| CWB certified for welding of Steel (CSA Standard W47.1, Division 2) |

| CWB certified for welding of Aluminum (CSA Standard W47.2, Division 2) |

| Professional Engineers Ontario |

| CLAC |

PROJECTS

Improving Safety and Productivity for Hammond Manufacturing

One of our customers recently purchased a brand new laser cutting machine that increased production while reducing the footprint in their facility. But there was a problem.

Maintenance Access Stand (Lifter)

Projects Maintenance Access Stand (Lifter) CHALLENGES Tight workspace Height adjustability Safe maintenance access Factory floor navigation SOLUTION A custom maintenance access stand was designed and

Pneumatic Material Handling Device

Designed and fabricated for a local manufacturing facility, this Vacuum Pneumatic Material Handling Device provides a safe ergonomic solution for lifting sheets of metal weighing up to 300 pounds.

Custom Sheet Lifter

Our team at Liftsafe engineered this electric powered telescoping sheet lifter for a valued client. The sheet lifter comes equipped with adjustable lifting fingers, worm and worm gear to prevent backlash, and a slip clutch torque limiter to prevent damaging the gears during operation.

Related Products

iNSPECTIONS

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

Structural Engineering

Liftsafe provides our clients with structural upgrades to existing support structures and crane systems.

Prestart Health

& Safety Reviews

Providing Prestart Health and Safety Reviews (PHSRs) for standard and custom solutions to ensure compliance.