Machine Guarding

Prioritizing machine guarding not only ensures regulatory compliance but also safeguards your employees and business from avoidable risks and costs, emphasizing our commitment to safety in the workplace. Every year in Canada, approximately 2,500 people are injured due to machine-related incidents. Many of these injuries are preventable with proper machine guarding.

Our experienced professionals handle the design and installation of machine guards with precision and expertise. We conduct risk assessments to identify potential hazards and create effective guarding solutions tailored to your needs. With regular inspections and maintenance, we ensure ongoing safety and compliance with industry regulations.

- Preventable injuries: Lack of machine guarding leads to unnecessary injuries.

- Legal requirements: Compliance with OSHA / OHSA regulations.

- Financial implications: Avoid fines, medical expenses, and increased insurance premiums.

- Safe work environment: Protect employees and minimize workplace accidents.

- Lack of Understanding: Many employers are unaware of machine guarding requirements.

- Improper Design or Installation: Inexperienced designers may make mistakes during installation.

- Failure to Consider All Risks: Comprehensive assessment involving various stakeholders is crucial.

- Inadequate Maintenance: Without regular inspections, machine guards can become hazards.

- Misplaced Responsibility: Employers must ensure proper machine guarding, not solely rely on manufacturers.

Key features

Skilled Technicians

Expert teams trained with 1,200+ hours annually to ensure safe, efficient inspections.

Digital Reporting

Wireless, paperless reporting with access to equipment records anytime, anywhere.

Fast Results

Wireless technology ensures inspection are processed quickly and without delays.

24/7 Access

Certificates, documentation, manuals, and reports always available through mobile access.

Standardized Inspections

40+ standard inspection types offered, making us your single source for facility compliance.

Flexible Solutions

Free, no-obligation audits help us tailor inspection services to your facility’s needs.

Cost & Time Savings

Reduce costs and extend the value of your equipment with efficient inspections.

Safety Compliance

Regular inspections improve safety, reduce risk, and support better workplace attendance.

Regulations in Canada

| Regulation |

|---|

| CWB Certified Welders (Steel and Aluminum) |

| CWB certified for welding of Steel (CSA Standard W47.1, Division 2) |

| CWB certified for welding of Aluminum (CSA Standard W47.2, Division 2) |

| Professional Engineers Ontario |

| CLAC |

Your Perfect Solution Awaits!

Projects

80 foot 1 ton

Jib Crane

Our team worked with Next Hydrogen in Mississauga to perform the design, fabrication, welding and painting operations for their new, large custom gantry crane at our facility.

Double Girder Top Running Overhead Crane

A recent large-scale project has our team installing replacement “Maintenance Travellers” for the underside of a suspension bridge over the St. Lawrence river.

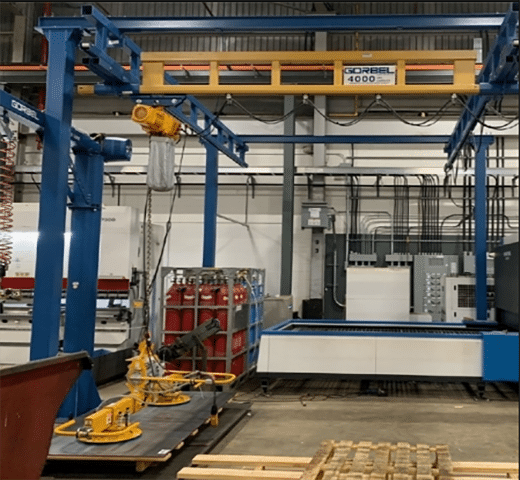

Woodstock Precision Machining Gorbel Easy Arm Crane

Liftsafe fabricated, installed, and inspected Workstation Cranes for a major Southern Ontario manufacturer—improving safety and efficiency by eliminating manual lifting.

Overhead Material Handling Equipment

Liftsafe installed a full line of Overhead Material Handling Equipment for a major manufacturer—boosting efficiency and ensuring compliance with safety standards.

Related Products

iNSPECTIONS

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

INDUSTRIAL CRANES & HOISTS

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

ENGINEERING SERVICES

Turnkey solutions with in-house engineering, design, and project management expertise.