Spanco

ALU-TRACK® WORKSTATION BRIDGE CRANES & RUNWAYS

Spanco

ALU-TRACK® WORKSTATION

BRIDGE CRANES & RUNWAYS

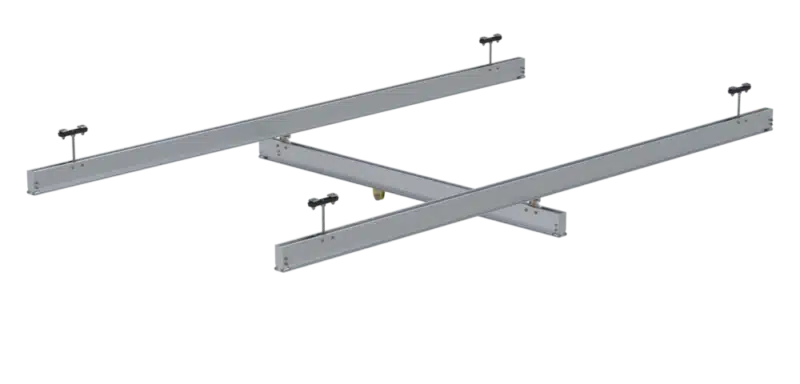

Spanco Alu-Track® Workstation Bridge Cranes and Runways combine agility and durability for superior material handling performance. Crafted from high-strength 6061-T6 aluminum alloy, these systems deliver lightweight construction, exceptional durability, and a maintenance-free design. With capacities ranging from 250 to 1,000 lbs, Alu-Track® offers a versatile solution for applications including workstation bridge cranes and monorail cranes.

Spanco Alu-Track® sets the standard for lightweight crane performance. Its extruded aluminum alloy ensures long-lasting strength and corrosion resistance, making it ideal for environments such as clean rooms, refrigerated areas, and moisture-prone settings.

The aluminum enclosed tracks significantly reduce overall system weight, improving bridge movement and efficiency. Particularly beneficial for Ceiling-Mounted Workstation Bridge Cranes, Alu-Track® systems minimize strain on building support structures, delivering a solution that is both cost-effective and highly adaptable.

- Applications: Workstation bridge cranes and monorail cranes

- Material: extruding hight-strength 6061-T6 aluminum alloy

- Capacity: 250 lbs., 500 lbs., or 1000 lbs.

- Bridge Span: up to 17 ft., dependent on capacity chosen

KEY FEATURES

Tailored Solutions

Customized systems expertly designed to optimize every workspace.

In-House Engineering

Fast design approvals and seamless project sign-off with our team.

Certified Components

Top-grade components built to meet all CMAA and CSA standards.

24/7 SERVICE

Crane inspections and maintenance available around the clock.

Cost-Effective Solutions

Efficient material handling systems that save time and reduce costs.

Enhanced Productivity

Solutions specifically designed to improve workflow and facility efficiency.

Qualified Welders

CWB-certified welders ensure full compliance with quality control measures.

Preventative Maintenance

Access plans to avoid safety incidents and compliance violations.

Specifications

| Feature | Spanco Alu-Track® Workstation Bridge Cranes and Runways |

|---|---|

| Type | Aluminum Ceiling-Mounted |

| Track Applications | Workstation bridge cranes & runways (including monorails) |

| Capacity | 250 lbs. to 1,000 lbs. |

| Bridge Length |

17 ft. standard Dependent on load capacity |

| Runway Support Centers |

15 ft. standard Dependent on load capacity |

| Runway Length |

Unlimited with splicing 30 ft. without splicing |

| Height |

Determined by application Lowest as practical to minimize trolley resistance |

Inspection Coming Up? We’ve Got You Covered.

DOWNLOADS

| Document | Format | Link |

|---|---|---|

| Resource Guide | Download | |

| Inspections Catalogue 2025 | Download | |

| Spanco Alu-Track Information Sheet | Download | |

| SWL/WLL/MRC – Importance Of These Abbreviations | Article | Click to read |

| CSA B167-16 (Crane and Hoist Compliance) | Article | Click to read |

Regulations in Canada

| Regulation |

|---|

| AISC Steel Construction Manual |

| OSHA 1910.179 |

| ANSI B30.11 |

| AWS D1.1/D1.6 |

| CMAA 74 |

Your Perfect Solution Awaits!

PROJECTS

Heavy-Duty Crane Systems for SW Ontario Manufacturer

A SW Ontario manufacturer approached Liftsafe with the need for high-capacity lifting systems to support high-volume, multi-shift production. The project required safe and efficient handling of critical components while maintaining strict uptime and scheduling demands, with a strong emphasis on safety, precision operation, and long-term serviceability.

Fast-Track Overhead Crane Installation for Automotive Manufacturer

Liftsafe rapidly performed on-site measurements and provided a same-day quote. Through strong coordination and detailed planning, the 5-ton overhead crane was engineered and installed on time to support the customer’s automotive manufacturing process

Custom Overhead Crane Systems for Electrical Transformer Manufacturing

A series of fully integrated overhead crane and runway systems were installed to support critical stages of the transformer manufacturing process. The systems enable safe, controlled, and precise lifting of large cores, tanks, and assemblies, improving workflow efficiency, protecting high-value components, and supporting consistent production quality, all while maintaining a strong focus on worker safety and regulatory compliance.

Six Ergonomic Workstation Cranes for Curtain Wall Manufacturer

Liftsafe designed and installed six custom ergonomic workstation crane systems featuring custom grabs, and precision hoists for a leading curtain wall manufacturer.

Related Products

iNSPECTIONS

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

INDUSTRIAL CRANES

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

Hoists

Safe, efficient lifting solutions for moving heavy loads across industrial and warehouse environments.