GH Wire Rope Hoists

Elevating Performance

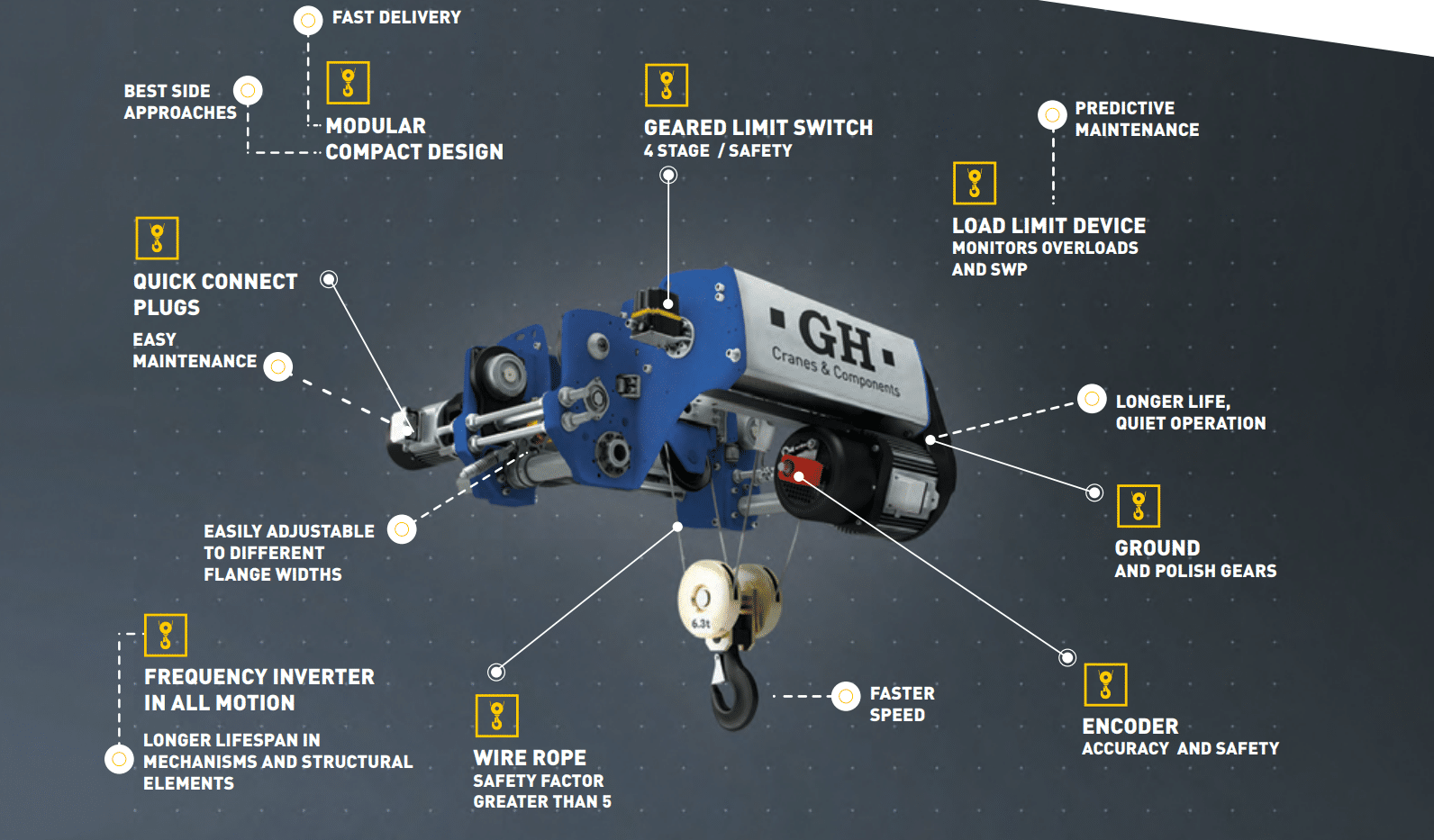

GH wire rope hoists, engineered for excellence, cater to a variety of applications including bridge, gantry, and semi-gantry cranes, adapting seamlessly to single or double girder setups with lifting capacities ranging from 800 Kg to an impressive 100 tons. Built with rugged and compact construction, these hoists ensure longevity and reliability, facilitated by modular construction that minimizes downtime during maintenance.

GH hoists offer a wide range of hook paths, lifting speeds, and adherence to working group FEM/ISO standards, allowing you to tailor the hoist to the specific demands of starts per hour and duty cycles. Equipped with a standard control system and real-time monitoring of the Safe Operation Period, GH hoists allow users to perform preventive maintenance, enhancing overall safety and operational efficiency. The hoists’ performance is rooted in principles of reliability, security, durability, and cost-effectiveness, all together in a compact design that ensures perfect balance for a seamless lifting experience.

Flexible

GH wire rope hoists are perfect for overhead, gantry, and semi-gantry cranes, adapting effortlessly to single- and double-girder applications. With lifting capacities ranging from 800 kg to 100 tons, our hoists are designed to meet diverse needs.

Reliable

Rugged and compact, GH hoists are built to last, employing modular construction for extended life and easy maintenance. Trust in the reliability of GH hoists for consistent, high-performance lifting.

Practical

GH hoists offer practical solutions with a variety of cable strands, enabling a wide range of hook paths and lifting speeds. Customize your hoist based on the demands of starts per hour and duty cycles, ensuring optimal efficiency for the loads being lifted.

Select your crane configuration

Overhead bridge cranes offer various configurations, with key considerations being the number of beams (single girder or double girder), support type (freestanding or building supported), and whether it operates as top-running or under-running. The choice between top-running and under-running depends on the building structure and lift operation space requirements. It’s crucial to thoroughly understand lifting task requirements and operational environment to select the appropriate system.

Hoists for top-running cranes

Top-running overhead cranes run on a fixed rail mounted on top of runway beams, allowing for single or double girder configurations. They offer advantages like no limiting capacity, increased lift height, and easy installation, making them suitable for handling both small and large loads.

Hoists for Under-Running cranes

Under-running overhead cranes, also known as underhung cranes, have a user-friendly design with wheels supported by the bottom flange of the runway beam. Typically set up as a single girder, they excel in wide bays, have a lighter design, lower costs, and allow for multiple crane installations.

Inspection Coming Up? We’ve Got You Covered.

Key features

Customized Systems

Tailored solutions designed to fit the unique needs of your workspace.

In-House Expertise

Design, engineering, fabrication, installation, and inspection all under one roof.

24/7 Support

Round-the-clock crane inspection and maintenance services available.

Certified Quality

Built with top-grade components that meet CMAA and CSA standards.

Expert Craftsmanship

CWB-certified welders ensure precision and strict quality control.

Cost-Effective Solutions

Engineered for performance without compromising your budget.

Enhanced Productivity

Optimize your workflow with efficient material handling systems.

Preventative Maintenance

Stay compliant and avoid downtime with proactive maintenance plans.

DOWNLOADS

| Document | Format | Link |

|---|---|---|

| Resource Guide | Download | |

| Inspections Catalogue | Download | |

| The Crane Fabrication Process at Liftsafe | Article | Click to read |

| CSA B167-16 (Crane and Hoist Compliance) | Article | Click to read |

Regulations in Canada

| Regulation |

|---|

| AISC Steel Construction Manual |

| OSHA 1910.179 |

| ANSI B30.11 |

| AWS D1.1/D1.6 |

| CMAA 74 |

Your Perfect Solution Awaits!

VIDEOS

Playlist

2:48

1:24

2:01

PROJECTS

Heavy-Duty Crane Systems for SW Ontario Manufacturer

A SW Ontario manufacturer approached Liftsafe with the need for high-capacity lifting systems to support high-volume, multi-shift production. The project required safe and efficient handling of critical components while maintaining strict uptime and scheduling demands, with a strong emphasis on safety, precision operation, and long-term serviceability.

Fast-Track Overhead Crane Installation for Automotive Manufacturer

Liftsafe rapidly performed on-site measurements and provided a same-day quote. Through strong coordination and detailed planning, the 5-ton overhead crane was engineered and installed on time to support the customer’s automotive manufacturing process

Custom Overhead Crane Systems for Electrical Transformer Manufacturing

A series of fully integrated overhead crane and runway systems were installed to support critical stages of the transformer manufacturing process. The systems enable safe, controlled, and precise lifting of large cores, tanks, and assemblies, improving workflow efficiency, protecting high-value components, and supporting consistent production quality, all while maintaining a strong focus on worker safety and regulatory compliance.

Six Ergonomic Workstation Cranes for Curtain Wall Manufacturer

Liftsafe designed and installed six custom ergonomic workstation crane systems featuring custom grabs, and precision hoists for a leading curtain wall manufacturer.

Related Products

Custom Fabrication

A collaborative approach to custom fabrication that enhances workplace safety and productivity.

Industrial Cranes

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

ENGINEERING SERVICES

Turnkey solutions with in-house engineering, design, and project management expertise.