GH Gantry Cranes

GH Semi-Gantry Crane

GH Semi-Gantry Cranes are engineered for heavy-duty applications that require a fixed path of travel but lack structural support on one side. Ideal for situations where spanning the full width of a workspace isn’t necessary, these cranes feature an elevated runway on one side and a ground-level runway on the other, creating an efficient and space-saving lifting solution.

Built with high-quality, long-lasting components, GH Semi-Gantry Cranes can be fully customized to your specifications and are available with lattice designs for exterior applications.

Traditional Gantry Crane

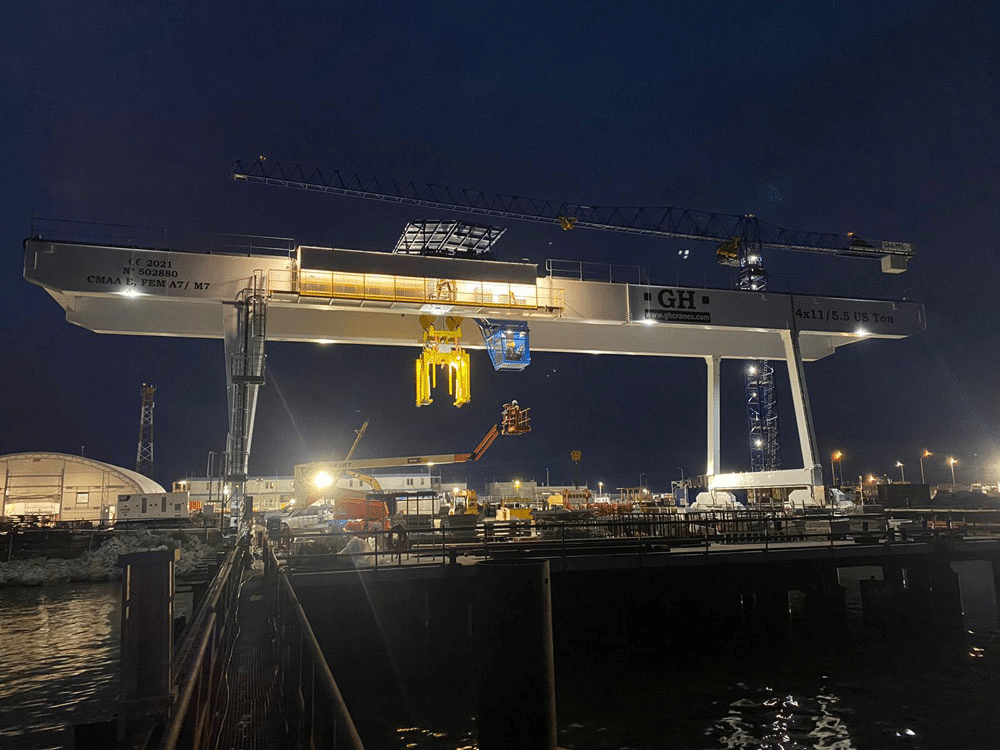

GH is a European leader in the design and manufacture of Gantry Cranes—also known as Portal Cranes or Goliath Cranes. With countless installations worldwide, GH gantry systems have become an industry reference for this crane style.

These gantry and portal cranes feature vertical legs that travel on traditional solid casters or, when required, rubber tires along fixed runways—typically at floor level. They can also incorporate lattice designs to withstand outdoor conditions such as wind exposure.

Every GH Gantry Crane is custom-engineered to your specifications, ensuring a perfect fit for your lifting application and environment.

Aluminum Gantry Crane

The GH Aluminum Gantry Crane is engineered to be lightweight and mobile under load, making it easy to maneuver throughout your workspace. Its folding design allows for compact storage, while the adjustable height enables the crane to accommodate varying headroom requirements when moving a load.

- Capacity: Up to 3200 kg

- Height: Adjustable from 7ft. to 10 ft.

- Span: 6 ft. (usable)

- Can be assembled and disassembled with ease

KEY FEATURES

Tailored Solutions

Customized systems expertly designed to optimize every workspace.

In-House Engineering

Fast design approvals and seamless project sign-off with our team.

Certified Components

Top-grade components built to meet all CMAA and CSA standards.

24/7 SERVICE

Crane inspections and maintenance available around the clock.

Cost-Effective Solutions

Efficient material handling systems that save time and reduce costs.

Enhanced Productivity

Solutions specifically designed to improve workflow and facility efficiency.

Qualified Welders

CWB-certified welders ensure full compliance with quality control measures.

Preventative Maintenance

Access plans to avoid safety incidents and compliance violations.

Inspection Coming Up? We’ve Got You Covered.

DOWNLOADS

| Document | Format | Link |

|---|---|---|

| Resource Guide | Download | |

| Inspections Catalogue 2025 | Download | |

| SWL/WLL/MRC – Importance Of These Abbreviations | Article | Click to read |

| CSA B167-16 (Crane and Hoist Compliance) | Article | Click to read |

Regulations in Canada

| Regulation |

|---|

| CWB Certified Welders (Steel and Aluminum) |

| CWB certified for welding of Steel (CSA Standard W47.1, Division 2) |

| CWB certified for welding of Aluminum (CSA Standard W47.2, Division 2) |

| Professional Engineers Ontario |

| CLAC |

Your Perfect Solution Awaits!

PROJECTS

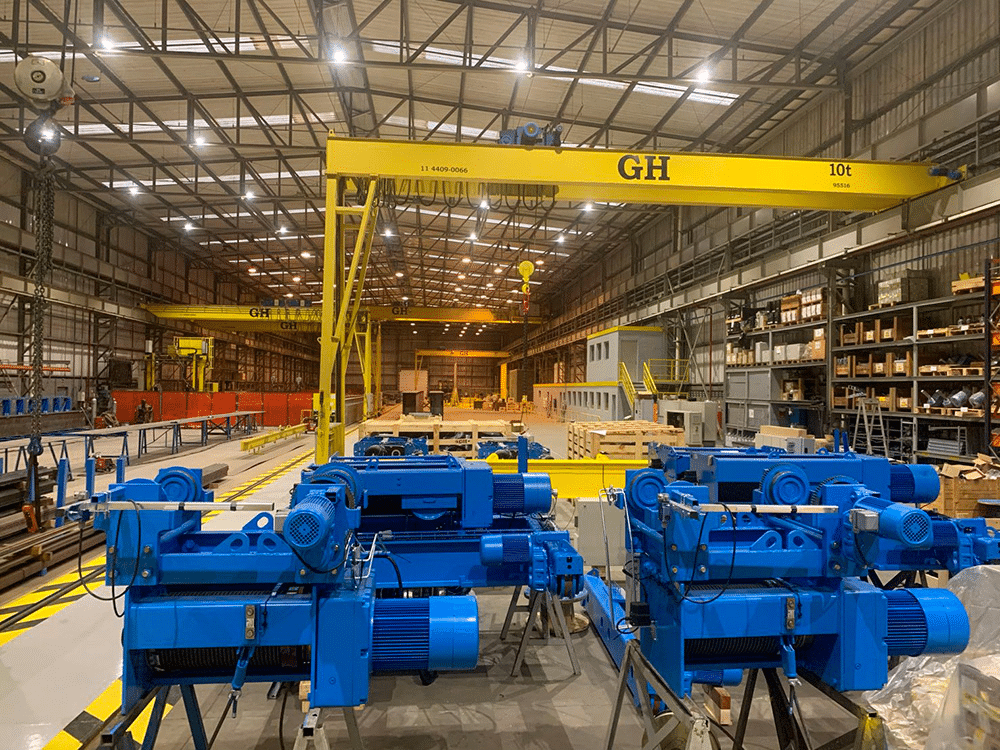

Heavy-Duty Crane Systems for SW Ontario Manufacturer

A SW Ontario manufacturer approached Liftsafe with the need for high-capacity lifting systems to support high-volume, multi-shift production. The project required safe and efficient handling of critical components while maintaining strict uptime and scheduling demands, with a strong emphasis on safety, precision operation, and long-term serviceability.

Fast-Track Overhead Crane Installation for Automotive Manufacturer

Liftsafe rapidly performed on-site measurements and provided a same-day quote. Through strong coordination and detailed planning, the 5-ton overhead crane was engineered and installed on time to support the customer’s automotive manufacturing process

Custom Overhead Crane Systems for Electrical Transformer Manufacturing

A series of fully integrated overhead crane and runway systems were installed to support critical stages of the transformer manufacturing process. The systems enable safe, controlled, and precise lifting of large cores, tanks, and assemblies, improving workflow efficiency, protecting high-value components, and supporting consistent production quality, all while maintaining a strong focus on worker safety and regulatory compliance.

Six Ergonomic Workstation Cranes for Curtain Wall Manufacturer

Liftsafe designed and installed six custom ergonomic workstation crane systems featuring custom grabs, and precision hoists for a leading curtain wall manufacturer.

Related Products

iNSPECTIONS

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

INDUSTRIAL CRANES

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

Hoists

Safe, efficient lifting solutions for moving heavy loads across industrial and warehouse environments.