Overhead Bridge Cranes (Heavy Duty)

For overhead crane equipment, custom crane systems, and crane maintenance services, Liftsafe is the trusted provider of choice. Our extensive industrial crane experience has been developed through decades of service and is built into every lifting solution we produce. We design and manufacture all major crane components in-house, allowing us to maintain strict quality control and deliver the right crane equipment for every application.

Our in-house engineering team has extensive expertise in design, safety, manufacturing process optimization, ergonomics, structural analysis, and regulatory compliance. The dedicated design, drafting, estimating, and project management teams at Liftsafe are capable of delivering complete solutions for manufacturing upgrades, safety improvements, and process optimization projects.

With over 30,000 sq. ft. of fabrication space—including a machine shop, fabrication area, paint booth, and assembly zone—Liftsafe specializes in turning complex concepts into reality.

Our lifting equipment specialists and product engineers work collaboratively to ensure the right system is selected for your facility. Connect with our team to receive qualified equipment recommendations or to learn more about which crane system is best suited for your space.

Need Guidance on Crane and Hoist Compliance?

Our detailed guide on CSA B167-16 provides crucial insights into crane and hoist regulations. Essential reading for anyone responsible for compliance and safety. Check out the full guide now.

KEY FEATURES

Tailored Solutions

Customized systems expertly designed to optimize every workspace.

In-House Engineering

Fast design approvals and seamless project sign-off with our team.

Certified Components

Top-grade components built to meet all CMAA and CSA standards.

24/7 SERVICE

Crane inspections and maintenance available around the clock.

Cost-Effective Solutions

Efficient material handling systems that save time and reduce costs.

Enhanced Productivity

Solutions specifically designed to improve workflow and facility efficiency.

Qualified Welders

CWB-certified welders ensure full compliance with quality control measures.

Preventative Maintenance

Access plans to avoid safety incidents and compliance violations.

Inspection Coming Up? We’ve Got You Covered.

Single Girder Overhead Bridge Cranes

Single Girder Top Running Overhead Cranes are designed to travel on top of a runway system that can be supported by either engineered columns or existing building columns. Liftsafe’s collaborative approach ensures that the overhead crane system you select exceeds expectations for both quality and reliability.

Single Girder Under Running Cranes (also known as “underhung” cranes) operate on wheels supported by the bottom flange of the runway beam, allowing the bridge to move smoothly along the runway. These cranes are most commonly used for lighter service and lower-capacity applications, utilizing an under running hoist and trolley that travel across the bottom flange of the bridge beam.

Crane capacity, height, span, and additional details are available upon request.

Working alongside our trusted and reliable suppliers, Liftsafe combines expert service to engineer both standard and custom crane systems.

Liftsafe can service the entire lifecycle of your product — from design and fabrication to installation, inspection, and maintenance.

Double Girder Overhead Bridge Cranes

Double Girder Top Running Overhead Cranes are designed to travel on top of a runway system supported by either engineered columns or existing building columns. These systems provide superior lift height compared to single girder or under running designs, as the bridge travels between the top of two beams for maximum vertical clearance.

Liftsafe also offers Double Girder Under Running Overhead Cranes, ideal for facilities with limited vertical clearance that still require high load capacity. Although this configuration is less common, Liftsafe’s in-house engineering team has the expertise and experience to design complete double girder under running systems that deliver enhanced lifting height and efficiency between the two beams.

Crane capacity, height, span, and additional details are available upon request.

Working alongside our trusted and reliable suppliers, Liftsafe combines expert service to engineer both standard and custom crane systems.

Liftsafe can service the entire lifecycle of your product — from design and fabrication to installation, inspection, and maintenance.

Your Perfect Solution Awaits!

Regulations in Canada

| Regulation |

|---|

| CWB Certified Welders (Steel and Aluminum) |

| CWB certified for welding of Steel (CSA Standard W47.1, Division 2) |

| CWB certified for welding of Aluminum (CSA Standard W47.2, Division 2) |

| Professional Engineers Ontario |

| CLAC |

Projects

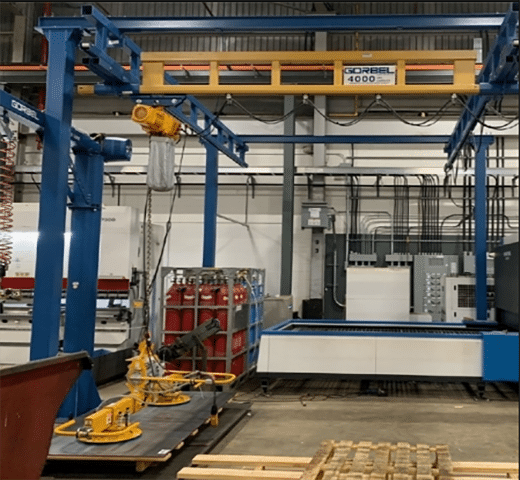

Workstation Crane Systems for Curtain Wall Manufacturer

Liftsafe engineered six custom workstation cranes for a curtain wall manufacturer, improving safety, reducing labor needs, and ensuring precise, damage-free glass handling.

Overhead Material

Handling Equipment

For a recent facility expansion, Liftsafe installed a full line of overhead and jib cranes, boosting productivity and ensuring full compliance with CMAA and CSA standards.

Polytainers Overhead

Bridge Crane

Liftsafe installed an overhead bridge crane with 136 feet of runway at Polytainers, enabling safe, efficient die and mold handling while maximizing existing manufacturing space.

Woodstock Precision Machining Gorbel Easy Arm Crane

Liftsafe fabricated, installed, and inspected Workstation Cranes for a major Southern Ontario manufacturer—improving safety and efficiency by eliminating manual lifting.

Related Products

iNSPECTIONS

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

INDUSTRIAL CRANES

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

Hoists

Safe, efficient lifting solutions for moving heavy loads across industrial and warehouse environments.