GH Under Running Electric Hoists

GH under running electric hoists are configured for under-running cranes in multiple configurations. Under-running bridge cranes, also known as under-hung cranes, have a user-friendly design with wheels supported by the bottom flange of the runway beam. These cranes are designed for capacities under 10 tons and are typically ceiling-supported for maximum floor space utilization.

Under-running cranes maximize the hook-end approach of the hoist due to the bridge beam being located under the runways. They are ideal for facilities lacking vertical clearance and are typically configured in a single girder design for lighter service and lower-capacity applications, but can be built in custom configurations.

Products

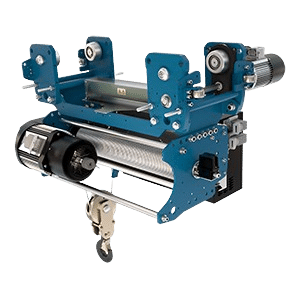

Low-headroom hoists

Low-headroom hoists are perfect for using in the small under-beam space in single-girder cranes. Choose between flat or angled wheels to suit your bottom flanges and running profile, to improve performance and increase the life of your hoist.

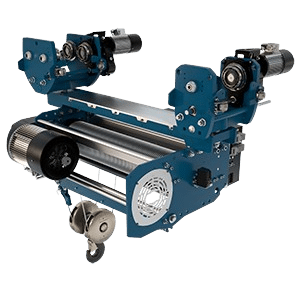

Standard-headroom hoists

Our standard-headroom hoists are the perfect solution when the amount of space under your single-girder crane is not critical, or when you are moving loads between halls.

This configuration is suitable for 1/1 and 2/2 reeving hoists.

Choose between flat or angled wheels to suit your bottom flanges and running profile, to improve performance and increase the life of your hoist.

Standard-headroom hoists ready for curves

This hoist is designed for applications that involve moving loads along curved paths and changes in direction. Choose between flat or angled wheels to suit your bottom flanges and running profile, to improve performance and increase the life of your hoist.

Inspection Coming Up? We’ve Got You Covered.

Key features

Customized Systems

Tailored solutions designed to fit the unique needs of your workspace.

In-House Expertise

Design, engineering, fabrication, installation, and inspection all under one roof.

24/7 Support

Round-the-clock crane inspection and maintenance services available.

Certified Quality

Built with top-grade components that meet CMAA and CSA standards.

Expert Craftsmanship

CWB-certified welders ensure precision and strict quality control.

Cost-Effective Solutions

Engineered for performance without compromising your budget.

Enhanced Productivity

Optimize your workflow with efficient material handling systems.

Preventative Maintenance

Stay compliant and avoid downtime with proactive maintenance plans.

DOWNLOADS

| Document | Format | Link |

|---|---|---|

| Resource Guide | Download | |

| Inspections Catalogue | Download | |

| The Crane Fabrication Process at Liftsafe | Article | Click to read |

| CSA B167-16 (Crane and Hoist Compliance) | Article | Click to read |

Regulations in Canada

| Regulation |

|---|

| AISC Steel Construction Manual |

| OSHA 1910.179 |

| ANSI B30.11 |

| AWS D1.1/D1.6 |

| CMAA 74 |

Your Perfect Solution Awaits!

PROJECTS

Fast-Track Overhead Crane Installation for Automotive Manufacturer

Liftsafe rapidly performed on-site measurements and provided a same-day quote. Through strong coordination and detailed planning, the 5-ton overhead crane was engineered and installed on time to support the customer’s automotive manufacturing process

Custom Overhead Crane Systems for Electrical Transformer Manufacturing

A series of fully integrated overhead crane and runway systems were installed to support critical stages of the transformer manufacturing process. The systems enable safe, controlled, and precise lifting of large cores, tanks, and assemblies, improving workflow efficiency, protecting high-value components, and supporting consistent production quality, all while maintaining a strong focus on worker safety and regulatory compliance.

Six Ergonomic Workstation Cranes for Curtain Wall Manufacturer

Liftsafe designed and installed six custom ergonomic workstation crane systems featuring custom grabs, and precision hoists for a leading curtain wall manufacturer.

Woodstock Precision Machining Gorbel Easy Arm Crane

Woodstock Precision Machining worked with Liftsafe to implement a workstation crane/easy arm intelligent articulated jib crane with a zero gravity feature for a repetitive light duty lifting application.

Specifications

| Features | Benefits |

|---|---|

| ALE-100/TN Electronic Limiter | Overload, loose wire rope, and motor overheating control. |

| Record and Control Function | Comprehensive data recording and analysis. |

| Anti-Collision Photocells | Enhanced safety by preventing collisions. |

| Weighing Display | Accurate weight measurement for precise operations. |

| Safety Brake on Drum | Ensures secure braking for enhanced safety. |

| Hook Blocking System | Prevents unwanted movement for increased safety. |

| Remote Control | Convenient operation from a distance. |

| Data Displayed on Remote Control | Easy access to critical data during operation. |

| Data Displayed on Radio Remote Control | Convenient data monitoring with radio remote control. |

| Load Control Hoist Versions | Improved control over hoisting operations. |

| Frequency Inverter | Enhanced control and energy efficiency. |

| Electronic Load Limit Device (ALE-100/TN) | Precise load management and safety. |

| Radio Remote Control with Display | Convenient remote operation with real-time data display. |

With the GH Core Box you will improve your crane’s performance with unparalleled control using our electronic load limiter, efficient hoist motor management, and prevention of over-temperature incidents. Gain valuable insights into your crane’s operations through comprehensive monitoring, including detailed operational data and incident logs. The Core Box goes beyond conventional monitoring by communicating parameters via a cellular network to GH Realtime, our proprietary data platform. Access advanced usage and maintenance services through the GH CRANES Customer Portal, providing real-time information on your crane’s operation.

How It Works:

Data Reception: Core Box gathers data from load cells, VFDs, and thermal sensors of the motors.

Processing Power: Core Box efficiently processes and records operating parameters and detected errors for insightful analysis.

Data Transmission: Transmit lifted load and SWP data to displays or radio controls, providing real-time information.

Connectivity Beyond: Utilize cellular network connectivity to seamlessly communicate with GH CRANES’ proprietary platform for advanced services.

Advantages:

All-in-One Integration: Enjoy the convenience of having Control, Monitoring, and Connectivity seamlessly integrated into a single device.

Accessory Connectivity: Connect to accessories such as Displays and Radio Controls for continuous monitoring of crucial data like Lifted Loads and Safe Working Period (SWP).

Non-Intrusive Connectivity: Communicate via 3G/4G networks, ensuring that the Core Box doesn’t interfere with your internal network.

Universal Compatibility: Retrofit Core Box to other crane brands, enabling monitoring and SWP calculation without disrupting their existing operation.

Related Products

Custom Fabrication

A collaborative approach to custom fabrication that enhances workplace safety and productivity.

Industrial Cranes

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

ENGINEERING SERVICES

Turnkey solutions with in-house engineering, design, and project management expertise.