ELECTRIC Chain Hoists

At Liftsafe, we pride ourselves on providing a diverse range of electric chain hoists, including options for single-phase and three-phase requirements. Our selection, featuring trusted brands like Kito, STAHL and CM, ensures that you receive top-notch quality, reliability, and longevity.

Discover the versatility of Liftsafe‘s electric chain hoists, offering solutions for heavy-duty lifting across a spectrum of applications. Our hoists are designed to handle industrial and commercial projects with cost-effective precision. Whether you’re in need of reliable solutions for overhead cranes, workstation cranes, or jib cranes, Liftsafe will support the entire lifecycle of your lifting equipment.

Products

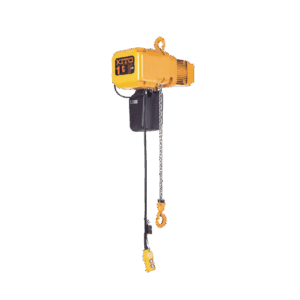

Kito ER2 Series

This Kito hoist delivers peak performance, ensuring seamless operation even in the harshest conditions. With its remarkably quiet operation and minimal vibration, it not only minimizes workplace noise pollution but also mitigates worker fatigue, thereby enhancing productivity. Crafted for practical durability, the ER2 guarantees worry-free performance.

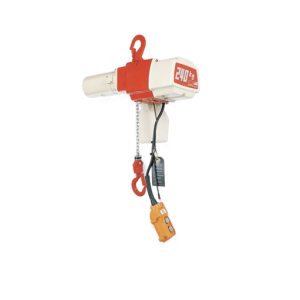

Kito SER Series

Engineered to surpass H4 industrial standards, the SER boasts a robust TEFC motor and a maintenance-free, self-adjusting pull-rotor brake. This innovative design ensures seamless operation, offering the endurance needed for extended lifts and prolonged shifts typical in industrial settings. The efficiency and reliability of the SER will meet your single-phase powered hoisting needs.

Kito ED Series

With the Kito ED Series simply plug into any standard 115 V wall socket and experience seamless lifting. With impressive speeds reaching up to 44 fpm, this hoist defies its size with its top performance. Engineered for optimal productivity and portability, the ED features a variable-speed option, allowing you to customize the pace to your specific application needs.

Inspection Coming Up? We’ve Got You Covered.

CM Shopstar

A robust hoist solution designed for industrial and commercial applications. Engineered to withstand rugged conditions, this durable hoist boasts high H4 duty cycles and a compact design perfectly suited for workstations and production lines. Equipped with a standard overload device, the Shopstar ensures safety by protecting the hoist, operator, and surrounding structure from overloads.

Stahl ST Series

The ST chain hoist series, offers extensive range, reliability, and low maintenance. With six load capacity variants, ranging from 125 kg to 6,300 kg, and versatile mounting options, including stationary, push trolley, and electric trolley, it offers tailored solutions for various applications. Engineered for safety with its patented direct suspension, the ST chain hoist is a top-quality choice for manufacturers.

CM Loadstar

Renowned as the industry standard, the CM Lodestar electric chain hoist has been trusted by generations of users for its unmatched power and reliability in material handling. Whether as standalone units, hoist/trolley combinations, or integral components of complete lifting systems, the CM Lodestar shines across various applications and industries.

Key features

Customized Systems

Tailored solutions designed to fit the unique needs of your workspace.

In-House Expertise

Design, engineering, fabrication, installation, and inspection all under one roof.

24/7 Support

Round-the-clock crane inspection and maintenance services available.

Certified Quality

Built with top-grade components that meet CMAA and CSA standards.

Expert Craftsmanship

CWB-certified welders ensure precision and strict quality control.

Cost-Effective Solutions

Engineered for performance without compromising your budget.

Enhanced Productivity

Optimize your workflow with efficient material handling systems.

Preventative Maintenance

Stay compliant and avoid downtime with proactive maintenance plans.

DOWNLOADS

| Document | Format | Link |

|---|---|---|

| Resource Guide | Download | |

| Inspections Catalogue | Download | |

| The Crane Fabrication Process at Liftsafe | Article | Click to read |

| CSA B167-16 (Crane and Hoist Compliance) | Article | Click to read |

Regulations in Canada

| Regulation |

|---|

| AISC Steel Construction Manual |

| OSHA 1910.179 |

| ANSI B30.11 |

| AWS D1.1/D1.6 |

| CMAA 74 |

Your Perfect Solution Awaits!

Projects

Polytainers Overhead

Bridge Crane

Polytainers worked with the engineering and crane fabrication team at Liftsafe to create an overhead bridge crane with 136 ft. of runways with added support structure.

Woodstock Precision Machining Gorbel Easy Arm Crane

Liftsafe fabricated, installed, and inspected Workstation Cranes for a major Southern Ontario manufacturer—improving safety and efficiency by eliminating manual lifting.

Liftsafe Boosts Efficiency with 13 Bridge Cranes

Our client needed their manufacturing lines upgraded to meet new project demands, which required reliable, heavy-duty cranes due to high demand manufacturing cycles.

Workstation Crane Systems Enhance Safety & Efficiency

Liftsafe provided ergonomic push & pull workstation crane systems with 2-speed electric chain hoists and custom load-balancing handling devices.

Specifications

| Feature | Kito ER2 Heavy Duty | Kito SER Heavy Duty | Kito ED High Speed | CM Shopstar Electric | CM Lodestar Classic | STAHL ST Chain |

|---|---|---|---|---|---|---|

| Capacity | ⅛ to 20 metric tonnes | ¼ to 3 metric tonnes | 100 to 480 kilograms | 250 to 1000 lbs | Up to 3 tonnes | 125 kg to 6,300 kg |

| Standards | CSA, ASME B30.16, ASME H4, IP55 | CSA, ASME B30.16, ASME 4, IP55 | CSA, ASME B30.16, ASME HST-1, IP44 | ASME B30.16 | ASME B30.16 | FEM/ISO, ATEX, IECEx, NEC, CEC, INMETRO, TC RU |

| Options | Various chain containers, lift lengths customization, trolley mount options | Various chain containers, lift lengths customization, trolley mount options | Dual speed, chain containers, lift lengths customization, trolley mount options | Unique rocker switch and comfort-fit design, with variable controls, durable chain containers, and swivel hook suspension options. | Harsh environment hoists available | Frequency inverters, explosion-protected design |

| Body | Die-cast aluminum, sealed, low headroom | Die-cast aluminum, sealed, low headroom | Die-cast aluminum, weather tight, low headroom | Cast aluminum alloy, epoxy powder-coat finish | N/A | Solid cast iron, short and compact |

| Gears | Alloy steel helical gears in oil bath | Alloy steel helical and spur gears in oil bath | Induction-hardened spur gears in oil bath | Lifetime lubricated with non-oxidizing grease | Lifetime lubricated with non-oxidizing grease | Overmounted drive shaft |

| Load Chain | Nickel-plated Grade 80 | Nickel-plated Grade 80 | Nickel-plated Grade 80 | CM Hoistaloy® Load Chain | Hoist alloy load chain | Custom options |

| Chain Guide | Heavy-duty cast iron, easily replaceable | Heavy-duty cast iron, easily replaceable | Heavy-duty cast iron | N/A | Hardened chain guides | Solid cast iron chain guide |

| Hooks | Forged carbon steel, self-closing, swivel bottom hook | Forged carbon steel, self-closing, swivel bottom hook | Forged carbon steel, self-closing, swivel bottom hook | Hardened, forged-steel, latch-type hooks | Hardened, forged-steel, latch-type hooks | N/A |

| Controls | Central electrical panel, plug-in connectors, dual-speed VFD | Central electrical panel, push button station, IP65 | Pendant control, in-line cylinder control, adjustable speeds | Industrial-rated control system, rigid-hook suspension | N/A | Frequency inverters from Magnetek |

| Brake | DC electromagnetic brake | Pull-rotor motor brake | Weston-style mechanical load brake, regenerative brake | Standard overload protection device | Standard overload protection device | Low-maintenance, asbestos-free electromagnetic disc brake |

| Motor | Three-phase, TEFC squirrel cage, Class B | Single-phase, TEFC squirrel cage, Class B | DC with rectifier, variable high speeds | Thermally protected, single- & 3-phase voltage options | Hoist duty motor | High ISO classification according to FEM/ISO standards |

| Overload Protection | Friction clutch, limit switch | Friction clutch, upper limit switch | Friction clutch, integrated high-performance clutch | Standard overload device | Standard overload protection device | Standard overload protection device |

| Overtravel Protection | Limit switch | Upper limit switch | Integrated friction clutch | N/A | Screw-type limit switches | N/A |

| Operating Conditions | -20˚C to +40˚C, humidity < 85% | -20˚C to +40˚C, humidity < 85% | -20˚C to +40˚C | N/A | N/A | N/A |

Related Products

Custom Fabrication

A collaborative approach to custom fabrication that enhances workplace safety and productivity.

Industrial Cranes

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

ENGINEERING SERVICES

Turnkey solutions with in-house engineering, design, and project management expertise.