Hazardous Environment Hoists

Specialized hazardous environment hoists are indispensable for carrying out tasks safely and ensuring compliance with laws and standards. Ensuring safety in demanding and risky settings is paramount for the seamless functioning of various businesses and sectors. These environments can potentially endanger both materials and personnel. Whether it’s within a chemical plant, petrochemical facility, or steel-making plant, hazardous conditions are present.

Products

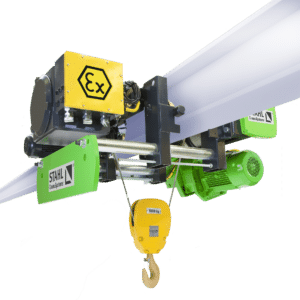

SH Ex Wire Rope Hoist

The STAHL Explosion-proof Ex wire rope hoists and SHW 8 Ex winches stand out as top-tier safety technology in the market, catering to a range of industries including chemical, petrochemical, pharmaceutical, food processing, power supply, shipbuilding, offshore, and LNG. These programs are built upon the solid foundation of our standard wire rope hoists and SHW winches, ensuring consistency and reliability. Compliance with rigorous ATEX directives and IECEx regulations for mechanical and electrical explosion protection is guaranteed.

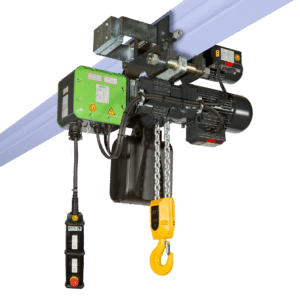

ST Ex Chain Hoist

The STAHL Explosion-proof ST Ex chain hoists represent cutting-edge safety technology, offering unparalleled protection for industries including chemical, petrochemical, pharmaceutical, food processing, power supply, shipbuilding, offshore, and LNG. Based on the modular ST chain hoist program, our ST Ex chain hoist program ensures reliability and consistency. With a safe working load range spanning from 250 kg to 6,300 kg for Zone 1 and Zone 21, and from 125 kg to 6,300 kg for Zone 22, these hoists are adaptable to various environments. Compliance with strict ATEX directives and IECEx regulations for mechanical and electrical explosion protection is guaranteed.

Lodestar Classic Clean Room

The CM Lodestar Classic Clean Room electric chain hoist provides performance tailored for clean rooms, from basic wipe-down to full wash-down setups. The Lodestar ensures reliability and consistency across diverse tasks, with features like stainless steel load chains and sealed, weather-proof construction. Choose from various capacities and customizations to meet your specific needs.

Inspection Coming Up? We’ve Got You Covered.

Key features

Customized Systems

Tailored solutions designed to fit the unique needs of your workspace.

In-House Expertise

Design, engineering, fabrication, installation, and inspection all under one roof.

24/7 Support

Round-the-clock crane inspection and maintenance services available.

Certified Quality

Built with top-grade components that meet CMAA and CSA standards.

Expert Craftsmanship

CWB-certified welders ensure precision and strict quality control.

Cost-Effective Solutions

Engineered for performance without compromising your budget.

Enhanced Productivity

Optimize your workflow with efficient material handling systems.

Preventative Maintenance

Stay compliant and avoid downtime with proactive maintenance plans.

DOWNLOADS

| Document | Format | Link |

|---|---|---|

| Resource Guide | Download | |

| Inspections Catalogue | Download | |

| The Crane Fabrication Process at Liftsafe | Article | Click to read |

| CSA B167-16 (Crane and Hoist Compliance) | Article | Click to read |

Regulations in Canada

| Regulation |

|---|

| AISC Steel Construction Manual |

| OSHA 1910.179 |

| ANSI B30.11 |

| AWS D1.1/D1.6 |

| CMAA 74 |

| EU (ATEX) |

| IECEx |

| CSA/US National Recognized Testing Laboratory (NRTL) requirements |

Your Perfect Solution Awaits!

Specifications

| Specification | ST Ex Chain Hoist | SH Ex Wire Rope Hoist | CM Lodestar Electric Chain Hoist |

| Industry | Chemical, petrochemical, pharmaceutical, food processing, power supply, shipbuilding, offshore, LNG | Chemical, petrochemical, pharmaceutical, food processing, power supply, shipbuilding, offshore, LNG | Various industrial applications |

| Explosion Protection | Full high-quality explosion protection | Full high-quality explosion protection | Full high-quality explosion protection |

| Gear Box Lubrication | Lifetime grease-lubricated | Lifetime grease-lubricated | Lifetime grease-lubricated |

| Motor | Heavy duty | Heavy duty | Heavy duty rated motors |

| Optional Features | Custom | Custom | Double DC Brake, AC Electrical Brake, Variable speed drive (VFD), Rotatable limit switch, Black phosphate or stainless steel load chain, Metal and stainless steel chain containers. |

| Clean Room Adaptability | yes | yes | yes |

| Certification | ATEX, IECEx | ATEX, IECEx | CSA/US National Recognized Testing Laboratory (NRTL) |

| Additional Information | International specialist for explosion protection technology, Extensive range for various zones | International specialist for explosion-proof crane technology, Cable pull programs and winch program available | Ideal for high duty cycles and tough applications, Documented RoHS compliance, Shipped in boxes made of recycled material |

PROJECTS

Heavy-Duty Crane Systems for SW Ontario Manufacturer

A SW Ontario manufacturer approached Liftsafe with the need for high-capacity lifting systems to support high-volume, multi-shift production. The project required safe and efficient handling of critical components while maintaining strict uptime and scheduling demands, with a strong emphasis on safety, precision operation, and long-term serviceability.

Fast-Track Overhead Crane Installation for Automotive Manufacturer

Liftsafe rapidly performed on-site measurements and provided a same-day quote. Through strong coordination and detailed planning, the 5-ton overhead crane was engineered and installed on time to support the customer’s automotive manufacturing process

Custom Overhead Crane Systems for Electrical Transformer Manufacturing

A series of fully integrated overhead crane and runway systems were installed to support critical stages of the transformer manufacturing process. The systems enable safe, controlled, and precise lifting of large cores, tanks, and assemblies, improving workflow efficiency, protecting high-value components, and supporting consistent production quality, all while maintaining a strong focus on worker safety and regulatory compliance.

Six Ergonomic Workstation Cranes for Curtain Wall Manufacturer

Liftsafe designed and installed six custom ergonomic workstation crane systems featuring custom grabs, and precision hoists for a leading curtain wall manufacturer.

Related Products

Custom Fabrication

A collaborative approach to custom fabrication that enhances workplace safety and productivity.

Industrial Cranes

Over 25 years of experience manufacturing, installing, inspecting, and repairing industrial cranes.

ENGINEERING SERVICES

Turnkey solutions with in-house engineering, design, and project management expertise.