Projects

CHALLENGES

- Employee safety

- Regulatory compliance

- Efficient material flow

- Precision lifting

SOLUTION

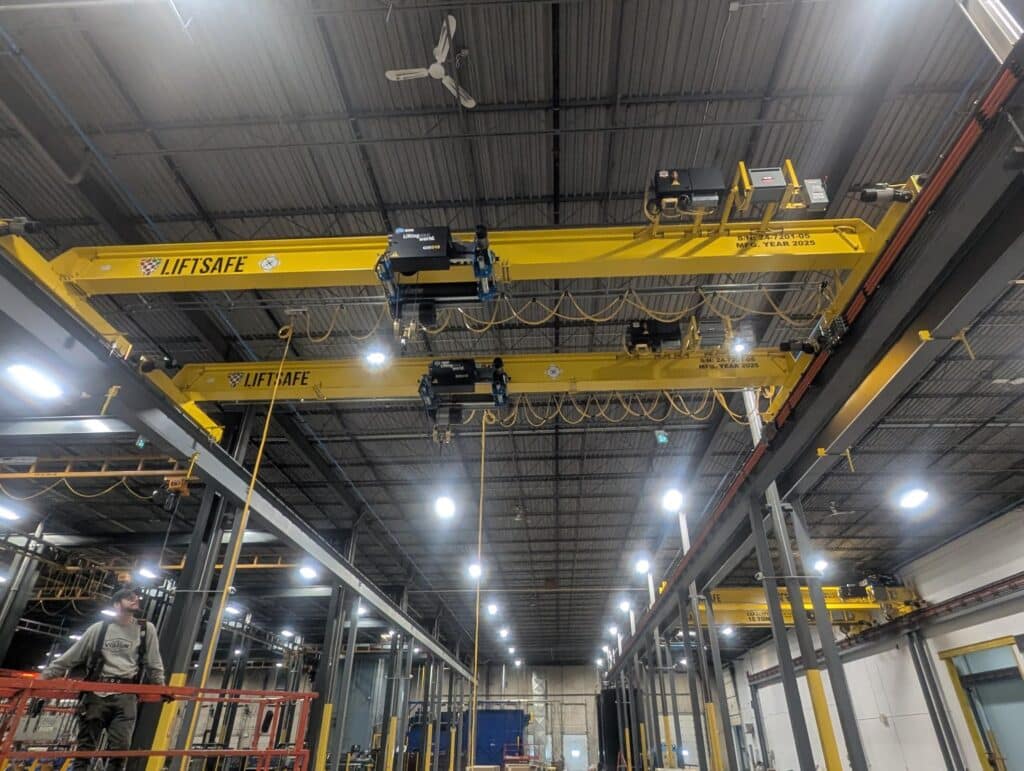

A series of fully integrated overhead crane and runway systems were installed to support critical stages of the transformer manufacturing process. The systems enable safe, controlled, and precise lifting of large cores, tanks, and assemblies, improving workflow efficiency, protecting high-value components, and supporting consistent production quality, all while maintaining a strong focus on worker safety and regulatory compliance.

Our overhead crane and runway systems play a critical role in supporting our customer’s transformer manufacturing process by enabling the safe, efficient, and precise handling of heavy and high-value components throughout production.

As a Canadian manufacturer at the forefront of the electrical transformer industry, our customer produces high-quality liquid-immersed transformers tailored to a wide range of electrical requirements. Their product portfolio includes distribution-class pad-mount and pole-top transformers, as well as power-sized units serving industrial and utility markets.

The crane and runway systems are integrated into key stages of the manufacturing workflow, allowing large transformer cores, tanks, and assemblies to be moved seamlessly between fabrication, assembly, and testing areas. By providing controlled lifting, accurate positioning, and repeatable material flow, the system helps reduce manual handling, improve worker safety, and minimize the risk of damage to critical components.

Liftsafe communicated clearly and consistently throughout the project, keeping us informed at every stage. Their team met all agreed timelines and was flexible in accommodating requested changes as our requirements evolved. The overall experience was professional and efficient, and we were very satisfied with the outcome.

— Client

The solution combines heavy-duty bridge crane systems equipped with GH hoists and crane components, along with Spanco enclosed track workstation crane systems fitted with Kito ER series electric chain hoists. This multi-system approach allows both high-capacity lifting and precise handling of lighter assemblies across the facility.

This material-handling solution supports consistent production quality, improves throughput, and provides the flexibility required to manufacture transformers of varying sizes and capacities helping our customer maintain their reputation for world-class quality, reliability, and on-time delivery.

Learn More about Liftsafe

Let us understand your challenges and help you find the perfect solution for your business.