Engineering Services

Liftsafe has an in-house team of professional engineers with extensive expertise in design, safety, manufacturing process optimization, ergonomics, structural analysis and regulatory compliance.

Offering clients a dedicated design, drafting, estimating, and project management teams, Liftsafe is capable of delivering on the full scope of your manufacturing upgrades, safety optimization, and process optimization projects. Coupled with over 30,000 sq ft of fabrication space that includes a machine shop, fabrication shop, paint booth, and assembly area, we specialize in bringing concepts to reality.

Our specialized in-house expertise offers our clients a turnkey process that covers design, engineering, implementation, and meets or exceeds any regulatory requirements.

How we can help

- Capacities

- Load Testing

- NDT Services

- Material Testing

- Analytical Reports

- Engineering Sign Offs

- Stamped Drawings

- Structural Upgrades

- PSHSR

- Structural Analysis

- Machine Guarding

- Reverse Engineering Services

Services

Risk assessments/safety audits

Liftsafe conducts health and safety audits to identify hazards and assess whether additional measures are needed to protect employees and visitors.

Reverse Engineering

Liftsafe provides reverse engineering services to address legacy components or products when original drawings or material information are unavailable.

Mechanical Engineering

Liftsafe specializes in “out of the box” thinking when it comes to developing and implementing cost-effective, simple, and reliable mechanical solutions.

Prestart Health and Safety Reviews

Liftsafe provides consultation and documentation to keep you compliant with regulations, ensuring your equipment and structures are safe.

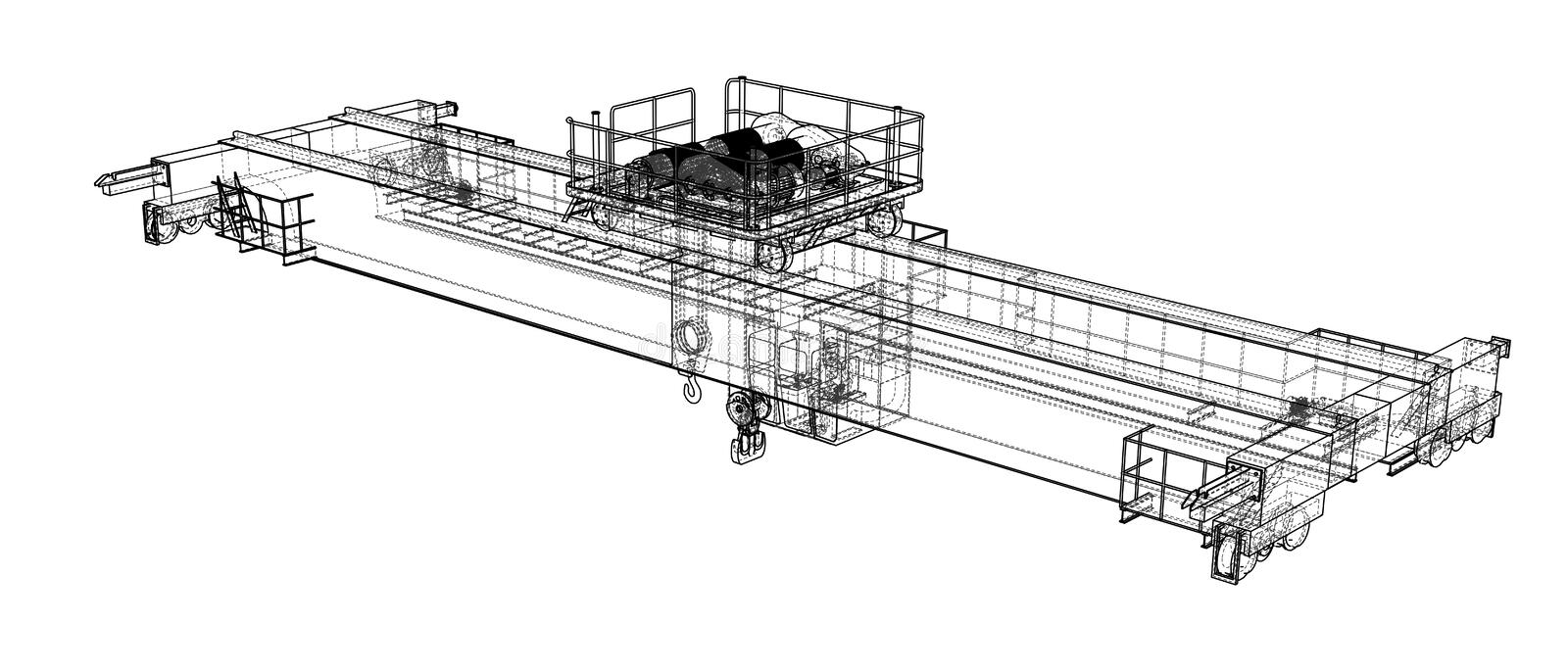

Structural Engineering

Liftsafe provides structural upgrades and evaluations for support structures and crane systems, offering reinforcement solutions and detailed reports.

Engineering Design

From cranes that boost facility capacity to ergonomic devices that reduce strain, our team delivers turnkey solutions using cutting-edge design software.

Custom Engineering

Concept

Taking a collaborative approach, we work with our clients to investigate all of the requirements of a project from a productive, environmental, usage and safety capacity. Then we use this information to inform our in-house design team.

Design

Our in-house design team combines their years of collective experience in manufacturing design and engineering with technical software and regulatory knowledge to design a solution for the project at hand to be sent for approval from our in-house engineering team.

Approval

Our in-house engineering team makes adjustments to make sure the initial design meets or exceeds all capacity, usage, environmental, safety and regulatory criteria and approves the project for fabrication.

Fabrication

Our team of CWB Certified welders brings the approved design concepts created by our design and engineering teams to life in our 30,000 sq ft fabrication facility.

Inspection

Once a project has completed the fabrication stage, it is inspected and tested to ensure all capacity, usage, environmental, safety and regulatory criteria are met or exceeded.

Installation

Once final inspection is completed, your project is ready for the installation phase, which includes physical installation, implementation of in-site training, adjustments (as needed), a Prestart Health and Safety Review, exemption letters, engineering sign-offs, and electrification according to CSA C22 standards (if applicable).

Your Perfect Solution Awaits!

Custom Fabrication

A collaborative approach to custom fabrication that enhances workplace safety and productivity.

Inspections

Helping businesses safeguard their operations and employees while staying compliant with safety regulations.

Prestart Health

& Safety Reviews

Providing Prestart Health and Safety Reviews (PHSRs) for standard and custom solutions to ensure compliance.